Data center-as-a-service startup EdgeCloudLink (ECL) plans to offer hydrogen-powered off-grid modular data centers, built in 1MW units, using 3D printing construction.

The new venture is building its first data center at its headquarters in Mountain View, California, using a construction 3D printer and a local building services company. It will be powered by hydrogen delivered from a local source, use a proprietary liquid cooling design, and need no diesel generators, ECL promises.

The pilot should be available in Q2 2023, and the design will undercut both cloud and colocation services, according to ECL founder and CEO Yuval Bachar, who has previously held senior data center positions at LinkedIn, Facebook, Cisco, and Microsoft, among others.

Zero emissions

"What we're trying to create is a zero-emission, zero water use community-integrated data center," Bachar told DCD. "That means a data center which is not impacting the community - but contributing to the community around us."

Adapting John F Kennedy's quote about the moon program, he says "We choose to do a fully sustainable data center in 2023 - not because it's easy, but because it's hard." The company has $7 million of funding from Molex and Hyperwise.

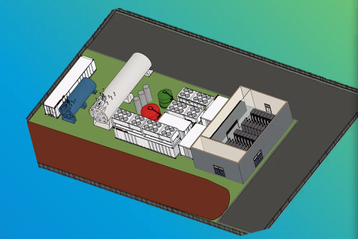

Bachar says ECL's model will allow it to build data center capacity quickly, within six months, and the light footprint will enable it to quickly pass zoning and safety restrictions. Each 1MW unit will be built on demand, using a 3D construction printer working with environmentally-friendly building materials. It will be powered by hydrogen fuel cells, supplied from an on-site tank filled by a local hydrogen supplier.

"We will bring everybody to see the first 1MW site that we're doing in Mountain View, California," Bachar said. "The reason we picked Mountain View is because it's considered a relatively difficult city to work with. Our assumption was that if we can actually handle Mountain View California, we can probably handle it anyplace on the face of the Earth."

Bachar says that today, data centers cost between $12 million and $15 million per MW to build, and ECL can come in at half that price. That means it is cheaper than today's colocation spaces. It also undercuts bare metal offerings from cloud providers with efficient hyperscale facilities, because these have a high markup currently leading to disillusion with the cloud.

Each data center will have its own hydrogen tank, and fuel cells to generate electricity for its primary power, along with batteries for backup. Where appropriate, it can also have a connection to the local grid for additional reliability.

The data center will have extra fuel cell capacity, with the units modularized so any failure will have limited impact: "We overdesigned the system completely. Everything is 2N, or 2(N+1), which allows six nines of reliability, the equivalent of a Tier IV."

For larger data centers, ECL would produce multiple data centers on the site, connected to a central meet-me room for network services. Each module will have its own independent hydrogen power source: "The beauty of this is, it's modular and the blocks are independent so we can Lego them in any way we want. We call it private colocation because each block is independent."

Customers will be able to order a data center with options including running it themselves, having ECL run it for them, or operating as a joint venture.

3D printed buildings

Construction 3D printers are a surprisingly good fit for data centers, if they are small, which suits ECL's modular design, he said: "We can print blocks one at a time, using sustainable concrete, with zero waste." When there is no construction on a site, ECL plans to offer the construction printer to the local community to make housing or community buildings: "There's no reason for us to sit on the printer."

ECL is using partners to build its Mountain View site: "They're building homes, and our requirements are much much simpler than a home. A data center is just a rectangle. We don't need sophisticated stuff. We don't have windows."

The local partners are helping steer buildings through California's zoning and seismic regulations. The shell consists of two thin walls filled with insulation: "It's it's a very, very strong structure and a very very insulated structure, which means that the elements outside have a much smaller impact on the inside."

After the initial building, ECL will own its own 3D printers and train staff up to use them: "We don't need to have a construction company. The printer is operated by three people. That's all you need to actually print a building: three people."

Hydrogen for power

Hydrogen is currently seen as an exotic option finding its way into backup, with Microsoft experimentally using fuel cells to build the equivalent of a 3MW generator in 2022. Bachar thinks hydrogen is ready for more than this, especially now the Biden administration's Inflation Reduction Act has prioritized building a hydrogen economy: "There is a whole effort in the US right now to build networks of hydrogen generation hubs that will be able to deliver by truck with no more than a two-hour drive."

In Europe, availability is patchy, but he believes it will develop: "We truly believe that the hydrogen availability issue is not going to be a major issue."

Wherever there is extra cheap electricity due to overproduction of renewable sources, the ECL data centers will be able to generate hydrogen, and contribute it to the local economy, says Bachar.

Hydrogen prices should be around $4 per kilogram, he says: "If it's available at $3 per kilogram, that works out at 20 cents per kilowatt hour," he says, which is cheaper than a lot of data centers can buy electricity now. Even if the price goes to $6, the facilities will be economical, thanks to their efficient cooling.

Each data center module will contain a mix of racks with anywhere from 5kW to 75kW each, enabled by cooling delivered where needed through a liquid-based rear-door cooling system: "There's no hot aisle - cold aisle isolation in our environment. It's all homogeneous temperature."

ECL stopped short of immersion cooling because Bachar believes it's not ready, it is not approved for exotic AI processors, and is mostly being hyped at the moment: "Most techs in data centers will not accept it. If you tell a data center tech to get a server out of the tub and deliver it dripping into the maintenance area, that's going to be very difficult."

Instead, a combination of air cooling, rear-door cooling and direct-to-chip cooling is enough to reach a PUE (power usage effectiveness) of 1.05, he says: "We have not reached the point that you cannot cool servers in a traditional way, which is a combination of air based plus direct-on-chip cooling with a very high efficiency."

ECL says it will open the first facility in Q2 2023, and quickly move into other areas. Members of the ECL board include Lily Yeung, vice president at Molex Ventures, Nathan Shuchami, managing partner at Hyperwise Ventures, and Dean Nelson, founder and chairman of Infrastructure Masons and CEO of Cato Digital.