Procurement officers are reassessing the disruption Covid-19 has forced on all sectors of the economy, with particular focus on the continuing impact on global supply-chains. Manufacturers, integrators, and customers are developing new processes whilst working together to maintain agile delivery and installation of critical IT infrastructure.

Many manufacturers are also reassessing supply-chain and plant capabilities in important customer regions.

Fifty-nine percent of shipping and freight professionals who responded to the, ‘Shipping and Freight Resource 2020’ survey, stated, ‘Their operations have been significantly affected by the pandemic’.

Across the supply-chain the requirement to simplify the ‘order-to-installation’ process is gaining momentum as resources are stressed and restrictions continue to impact logistical capabilities.

In today’s increasingly complex technology space environments, data center cabinets can require up to 35 additional products to complete the deployment of each rack. Untested infrastructure components, cables, hardware, electrical grounding, and blanking plates each contribute a risk to effective functionality, efficient operation, and physical fit.

2021 has continued this uncharted territory with possible restrictions hanging over all industries as well as the public, and these are likely to remain for some time to come.

With that threat, the need to keep staff and visitors separate and safe during their minimized time within enterprise and data centers is essential.

CPOs state that they lack the capability to identify risks in their supply chains. CPOs, together with their organizations, have been redesigning their supply chains, although many still struggle to access the data to help them measure the chain’s overall health.

A process that is helping a growing number Panduit installers and end customers is the supply of preconfigured modular solutions based on a single SKU.

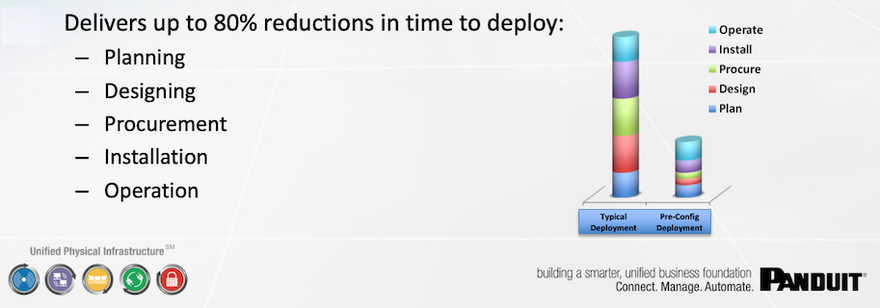

This allows customers to reorder assessed, tested, and optimized cabinets containing all the components required for specific solutions. This capability ensures infrastructure that provides reliable, high-performance results in a specified technology space. It has been found that preconfigured cabinets can save up to 80 percent of on-site deployment time.

Rack densities are increasing and the need for effective thermal and device management is paramount as hot spots are potentially fatal to active technology.

Chiefly, the pre-configured option is a tier one customer solution which reduces ordering complexity and the need for onsite construction. This will then offer a system solution rather than a box of parts that require hours of construction.

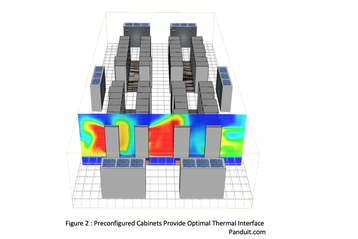

The cabinet configuration is pre-engineered and validated to the customer’s specifications. In many cases, complete cabinet systems are tested within Panduit’s extensive thermal lab to ensure customer and safety thermal and environmental parameters are met. This guarantees cabinets arrive on site ready to be populated with active components as well as optimised for power, space, speed, and performance.

Assured air containment and sealing systems within the cabinet or pod can assist in a reduction in cooling energy by as much as 40 percent. This solution’s development is the result of a partnership of over 10-years with Cisco and other data center industry suppliers on standardized converged infrastructure appliances.

As compute density continues to increase, the heat generated within the cabinets requires proper inlet air conditions to ensure server, switches and storage provide an optimal thermal interface to allow airflow across the hot surfaces.

With procedures and software tools developed over a decade, hardware is tested in a simulated data center environment to maximize equipment power consumption efficiency and heat dissipation. Customers are supplied with key performance data which is collected to verify all equipment operates within expected thresholds.

Delivered as a dynamically load rated cabinet, optimized for space and scalability, it is ready to receive the active equipment, as well as the supplied complete color coded and sized connectivity components (cables; copper and fibre), cable managers, grounding, and bonding system, intelligent PDUs, patch panels and blanking panels.

Utilizing the supplied easy-to-follow instructions guide and elevation diagram simplifies and reduces the time taken to complete the build and have the units available for installation. It is estimated that this saves between nine and 14 hours of construction time per cabinet.

This next step in logistics also greatly reduces packaging and additionally assists supplier and customer to remove substantial amounts of waste packaging from the product and supply-chain cycle.

Large and small-scale operations can, over time and after numerous MACs (moves, adds and changes) lose track of device locations. Therefore, asset management is essential and device traceability within the cabinet environments is simplified using monitoring and sensor systems such as SmartZone.

Customers can maintain effective device mapping within cabinets and across time, ensuring MACs are reported and changes to topology recorded.

Wireless environmental monitoring increases the system’s capabilities to record and analyze real time environmental conditions and alert the system for automated response to any unplanned changes in conditions.

When human intervention is required, the system will notify the site engineer or systems management of the situation and provide analysis of the problem. An engineer is dispatched with the equipment required to resolve the problem, without the need to return a second time.

The pandemic highlighted on-going challenges with the procurement process many organizations follow. Today’s converged IT infrastructure solutions accelerate and can simplify design procurement and deployment cycles for site management.

Panduit’s solution allows customers to plan a streamlined process in less time and with reduced errors and waste, providing an easy route to expanding or renewing a data center or large enterprise infrastructure projects.

More from Panduit

-

Sponsored Connecting the boxes: Secure your data

-

-