In part one of this two-part article on the evolving data center environment, we discussed the operational challenges from a data center interconnects (DCI) perspective. In addition, we discussed the importance of testing transceivers before they are deployed in live networks. In part two, we take a look at emerging transceiver interfaces, steps for commissioning DCI links and best-practice testing solutions for DCIs.

Emerging interfaces for DCIs

There is an ongoing effort to make 400G less expensive in order to enable high volume 400G deployments for longer-reach requirements. As shown in Figure 1, new technologies including new proposals such as coherent pluggables (i.e. ZR and ZR+) show that the area of transceiver development continues to evolve.

Figure 2 shows that data center optics are complimented by a wide range of other evolving technologies within servers, between servers, up to top of rack as well as between Tier 1 to Tier 2 switches and all the way to the DCI. When designing their operations, data centers benefit from flexibility and impressive breadth of solution offerings. However, as mentioned in part one of this article series, supporting all these different technologies is a challenge from an operational perspective—a very big challenge for transceiver manufacturers, network equipment vendors and vendors of supporting equipment alike to support all these different technologies in a nimble, fast-paced and cost-effective fashion. For more information on this topic, watch EXFO’s webinar Data center and DCI optics: a look ahead.

Key steps to follow when commissioning DCI links

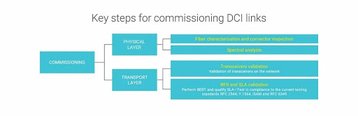

Maintaining the speed at which data center operators and web scale companies want to evolve their networks requires an absolute minimum of human touch points during installation. Implementing a strategy that automates certain processes will become critical. In addition, best practices such as connector inspection, link verification and fiber characterization are required to ensure that networks run smoothly. When it comes to validating the physical layer of a network, inspecting and cleaning of fiber connectors and qualifying the fiber link continue to be the most basic, yet most essential, steps (see Figure 3). Ensuring that the basics are covered is important since dirty connectors are the number one cause of fiber network failures—a cause of failure that can be easily avoided through proper inspection. For more information on these issues please watch EXFO’s webinar Connector inspection and cleaning: why is it vital for MPO connectors?.

Once the physical layer is validated, the next step is to qualify and/or troubleshoot the transport layer. And the first step in that process is to ensure that transceivers are fully functional and properly validated before they are installed in any network. Recommended transceiver testing procedures include validation of a number of critical parameters of each transceiver including PIM, optical power, crosstalk, power consumption and temperature. Due to the sheer volume of transceivers throughout a network, validation needs to be quick and easy.

DCI links should be qualified in terms of quality of service (QoS) parameters where the service level agreement (SLA) of the link is fully validated. This is done using standardized tests such as BERT, RFC 2544 and Y.1564 that measure key parameters like throughput, latency, packet loss and packet delay variation (see Figure 4). Results are saved for reference and reports can be generated or shared. Comparatively, in the data center where lengths are shorter, operators typically only test transceivers, direct attach copper (DAC) cables and active optical cables (AOC), but not link performance.

Conclusion

Data center and webscale operators are dealing with the challenge of supporting the constant evolution and sheer volume of pluggable transceiver optics in use. To properly handle this challenge, operators need solutions that meet the testing requirements for today’s optics combined with a design that is inherently flexible, one that’s able to adapt as new transceiver types emerge. Ideally, they need a transceiver testing solution that is modular so that as new pluggable optics are introduced, operators can simply adjust their testing strategy to the newest technologies, as required. This lowers CAPEX and waste or guarantees ROI on test equipment by eliminating the need to replace entire platforms or testing modules.

To keep up with the massive number of transceivers that require validation, an automated testing approach is required. Automating the different testing steps required during turnup, troubleshooting and commissioning is a must have. Single one-button testing that can validate any type of optics (i.e., QSFP28, AOC, QSFP-DD), check that all the key parameters are up to standard and provide a clear pass/fail indication. This can save untold amounts of transceiver-testing time and avoid fiber outages that would otherwise have resulted from defective transceivers beings installed in live networks. In addition, since data center operators typically keep onsite staff to a minimum, validation and troubleshooting must be able to take place remotely through a centralized remote control (see Figure 5).

Finally, data center testing solutions should be flexible and automated to ensure operators have what they need to enable faster and more reliable data center transformations, as well as tackle even the most daunting transceiver testing challenges.