Demand for data in India is soaring and hence the number of data centers is increasing rapidly. The new hyperscale facilities are much more power hungry and designed with Tier IV levels of uptime assurance. Unfortunately, the grid power in the country has not been keeping pace in terms of the capacity, reliability and quality of power supplied.

As a result, more than 95 percent of data centers in India are practically dependent on frequent use of diesel generator (genset) backup power system. But at times even this backup. Whom do you blame?

The challenge and the solution

There should be no room for downtime in a data center design. In the event of a grid power outage, the emergency backup power of diesel gensets should start in less than 25 seconds to avoid interruptions in operations. However, at times these gensets may just refuse to respond as expected, causing the worst nightmare for the data center operating team. The standard design practice of n+1 redundancy also can’t avoid this possibility.

The delay in start-up or scaling-up is not due to the genset itself, but is often a result of an inadequate fuel management system. Unfortunately, this aspect may get ignored or underplayed during the project design and execution where the focus remains on highly visible and costly elements like the genset itself.

This paper discusses the fuel management system in detail including its objectives, components, design and value in avoiding costly downtime. As well as being designed into new facilities, a system can also be retrofitted in an existing data center.

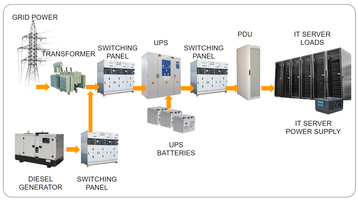

Power supply architecture

The primary source of power at the data center is typically the local power grid. In case of a grid power interruption (which is not so uncommon in India), a backup power source is essential. This is fulfilled through a diesel generator power plant within the data center premises. This also includes on-site storage and handling of fuel (diesel) with underground tanks and anetwork of pipelines connected to the generator room.

In the event of grid outage, an automatic mechanism will seamlessly switch the facility from grid power to diese; power. An intermediate emergency power backup is provided by a battery operated UPS system for the IT load. No direct backup power is available for the CRAH (computer room air handler) and chiller units in the server room, so the diesel backup power needs to start and ramp-up as fast as possible to take over the entire load.

Fuel management system

If gensets fail to start or to synchronize quickly, it can be due toi an inadequately designed fuel management system.

By nature, diesel fuel deteriorates over time. If it iskept idle (either in a storage tank or inside the diesel generator itself) the rate of degradation is faster. If this degraded fuel is fed into the genset, it will lead to sludge formation, clogging of filters and several other problems.

In many markets including India, there is a trend towards the use of ‘clean fuel’ which has lower sulphur content. Blended with biodiesel and other additives, this can ensure clean burning and reduce harmful emissions. This is a good move in principle, it is also a cause of potential trouble because, this cleaner grade of diesel is prone to faster decomposition and sedimentation when stored for a long time in the tank.

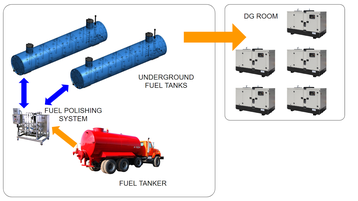

A fuel management system provices critical controls at various stages of fuel handling, right from the intake at the tanker unloading bay to intermediate movement between the storage tanks, supply through a network of pipelines, day tank and final supply into the genset. Leaving these handling operations to manual judgement can allow errors. Automated measurement, and control of fuel quality and transfers will enhance efficiency, reliability and cost optimization.

Can you retrofit it?

For any new generation data center with hyperscale capacities and Tier IV reliability, use of a full-fledged fuel management system is mandatory. But even for older data centers, it is a worthy upgrade to consider so as to stay competitive and avoid costly downtime in the future. Some of the reasons why older data center should go for the upgraded fuel management system are listed below;

- When a data center hasbeen in operation for some years,pollutants and impurities will collect in the fuel tank and can cause a genset to fail in future

- Older manually operated systems are prone to errors and safety lapses. These systems will also not detect fuel leaks. leading to fuel wastage and higher operational costs

- Older systems only provide for one direct connection between the fuel tank yard and generators. This single point of failure is a risk that can be avoided with an upgraded fuel management system

- An inadequate fuel management system can hinder future capacity expansion and prvent Uptime certification

What's in a fuel management system?

Fuel management at the data center site involves management of:

- Quality:

Maintaining the right fuel quality is crucial across the life cycle of diesel from the moment it enters the storage tank till its consumed in the genset. - Capacity:

This largely depends upon factors like how long the backup power is required to run and the overall space available. - Other factors:

Regulatory guidelines inlcuding CCoE and CPCB govern the design. Other key factors include; automatic monitoring of fuel levels, detection of leaks and theft, measurement of fuel consumption and providing real time insights

Points to ponder

One of the key objectives of the fuel management system is to provide clean filtered fuel throughout the system, from storage tank to the day tanks. This is achieved by a fuel polishing unit that helps filter out impurities like solid particles, water ingress, sludge and sedimentation.. It not only cleans the fuel at the intake/entry point but also during circulation of fuel across the tanks. The key benefits of a fuel polishing system are:

- Reduction in maintenance expenses

- Less likelihood of failure of fuel injectors

- Lesser buildup of sludge (sediment, rust, water, etc...)

- Reduced noise and smoke during generator operations

Sometimes, additional fine filtration system are included between day tank and engine to prevent injectors from choking

By design, the fuel management system provides redundancy in the piping network between the storage tank and the day tank in the generator room. Two routes of piping ensures mean there is no single point of failure. The system switches automatically to the alternate route uf the primary one can’t be used.

Diesel is a costly fuel and any pilferage can be quite expensive. The fuel management system incorporates multiple check-points and metering to maintain an accurate accounting of fuel consumption. This is also helpful in measuring the efficiency of gensets if required.

The storage tank is designed to hold enough dfuel to run the facility for up to 48 hours. However, anticipating situations where this storage may not suffice, a fuel management system whould provide for the rapid bunkering of the tanks in case of prolonged shutdowns.

From a safety viewpoint, the fuel management system incorporates technologies like fusible link valves that evacuate the day tanks more quickly in case of fire in the power house. A spillage tank arrangement under the pipe trench inside generator room will also help avoid fire.

A leak detection system across the fuel pipeline helps detect oil pilferage. It can be connected to the central building management system (BMS) to raise alarms.

Finally, the fuel management system is also required to provide adequate security and protection of the sensitive fuel storage and handling areas through fencing and secured access control.

Key components

- Tank Yard

- Underground tanks preferred due to better safety

- Tank capacity (std. 90kL - IS10978 std or usage requirement/ space constraint)

- Tank size 13-14 m length x 3.15-3.45 m height

- Tanks redundancy N+1

- Space considerations

- Provide for turning radius of the oil tanker

- Provision of “dike wall” around each tank - Fire protection & fighting system

- Proper earthing system to provide to the underground tanks

- Fuel polishing unit

- one running and one standby : (n+n)

- Pump + filter assembly

- Fuel transfer pump

- n+n or n+1 redundancy

- Canopy with electrical panel

- Fuel input flow meter

- Instrumentation + earthing needed for each tank in the DG room

- Leak detection system - High resistance leak detection to give alarm

- Related to the DG Room

- Spillage/settling tank fitted in DG room

- Fuel transfer pump - from storage tank to day tank

- Max limit for the day tank is 990 L / DG set as per the CCoE norms

- Automation - valves, instrumentation - connected to fuel automation system

- Panels + PLC for control purpose

- Fuel Fire safety system

- Piping design

- Tank isolation / Dike walls between two tanks

- Fire hydrant system for tank yard

- Fire alarm system and sprinkler system

- Fire cordons between bays inside generator room

- Explosion proof electrical equipment (eg light switches) inside tank yard

Conclusion

The cost of downtime in a data center is far more expensive than in any other industry. Fuel contamination due to sedimentation, impurities, decomposition as well as water ingrace are the main factors causing malfunctioning of diesel generators. Domain experts such as the Uptime Institute and The Society of Automotive Engineers (SAE) place a high degree of importance on fuel cleaning and polishing to ensure reliable operation of the generator set.

A robust and well designed fuel management system ensures that the backup power solution will be able to operate with very high reliability, responsiveness and at a lower operating cost. This not only applies to new projects, but can also be retrofitted into existing data center facilities.