Liquid cooling specialist GRC (Green Revolution Cooling), has redesigned its Iceraq product to deliver higher efficiency.

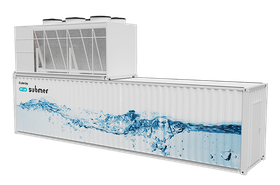

The Series 10 immersion cooling system has a new look with flatter surfaces and is more compact to save floor space. One immersion cooling tank can now cool up to 200kW in a 42U rack installed horizontally. The first customer is the Texas Advanced Computing Center (TACC).

Iceraq gets smarter

With the new version, the containment area is integrated, so there's no need for external containment decks. The new design means units can be placed end-to-end, without a walkway, so data center operators can pack the units in more tightly. The system looks neater, with cosmetic panels that disguise cables and plumbing.

The tank is filled with GRC's ElectroSafe mineral coolant, and heat is removed by secondary water cooling. If warm (32C) water is used in the secondary circuit, the tank can contain up to 200kW of IT power, handled by up to four power distribution units (PDUs) mounted at the rear of the rack. Networking and power connections are accessible simply by opening the lid.

The capacity can be increased to 368kW per tank, at an efficiency cost, if chilled water at 13C is used in the secondary circuit. GRC has said it is planning to increased power capacity even more in future, using a 50 percent larger brazed plate heat exchanger.

The first customer will be a long-term proponent of immersion cooling, the Texas Advanced Computing Center (TACC). TACC's Frontera supercomputer uses three different liquid cooling technologies, with GRC immersion systems handling the GPU-intensive subsystem.

The system monitors for leaks continually and provides real-time data on water and coolant temperatures, as well as pressure, coolant pump power consumption, and coolant pump speed, and can be monitored with Schneider Electric's DCIM.

The system has a 10 percent lower TCO and an 18 percent lower capex than the previous model, GRC says.