Construction on a 3D-printed building set to be used as a data center in Heidelberg, Germany, has been completed.

Real estate developer and investor Kraus Group handed over the facility – known as the Wavehouse Campbell Heidelberg – to local cloud and data center provider Heidelberg iT Management at an event this week attended by DCD.

Known as Baufeld 5 and located at Billie-Holiday-Strasse 7 in Baden-Württemberg, the single-story building totals just under 600 sqm (6,600 sq ft).

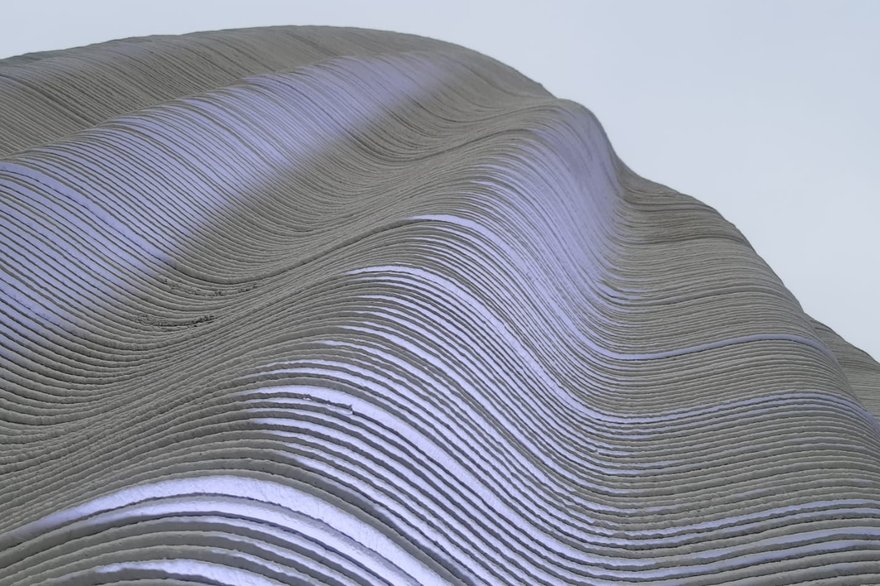

It is reportedly Europe’s largest 3D-printed structure, the first 3D-printed industrial building globally, and the first 3D-printed data center globally.

Work on the facility began last year using a BOD2 3D construction printer. Construction on the shell is complete and Heidelberg iT will now build out the white space and electrical room.

The data center will offer 500kW and have capacity for around 100 racks. The fit-out is expected to be complete towards the end of the summer. The IT firm has a long-term lease on the site.

The facility was printed using around 450 tons of printing concrete from Heidelberg Materials. The concrete is 100 percent recyclable and contains a binder that can reportedly achieve a 55 percent CO2 reduction rate compared to pure Portland cement.

Partners on the project include Peri 3D, which is part of the scaffolding firm Peri Group, as well as architecture firms Mense-Korte and SSV.

“We are very proud to have realized our largest building to date with this project," said Dr Fabian Meyer-Brötz, managing director of Peri 3D. "The special shape and the parametric design provide insights into the immense design freedom that the Cobod BOD2 3D printer enables."

Cobod – privately owned by General Electric, with CEMEX, Holcim, and Peri as key shareholders – manufactures the BOD2 construction printers. The actual printing took around 140 hours, equivalent to printing four square meters of building per hour.

Though officially launched in 2007 after merging with MEG Kommunikationssysteme GmbH, Heidelberg iT can trace its roots back to the launch of its first data center in cooperation with MVV Manet GmbH in 2001. A second facility was launched in 2016. The company is set to launch a third – traditionally constructed – data center in the coming months that will also offer 500kW.

In the US, EdgeCloudLink (ECL) plans to offer hydrogen-powered off-grid modular data centers, built in 1MW units, using 3D printing construction.

DCD will be profiling the story behind the new 3D-printed data center in issue 52 of the DCD>Magazine. Subscribe for free today.

More in Construction & Site Selection

-

-

-

Discussion Networking break

More in Europe

-

-

-

Discussion Networking break