Dogged by supply chain issues, inefficiencies and wastefulness, current manufacturing methods in the data center space are far from conducive to achieving the greener, cleaner industry we are fighting to create. With sustainability now top of the agenda for data center developments, there has to be another way.

Enter, Additive Manufacturing, or AM – an industrial scale 3D printing solution that global technology company EOS believes could help overcome the limitations we face today. As EOS expands to embrace the data center industry, Data Center Dynamics spoke to Ho Kei Leong, EOS’s vice president of Applied Solutions (APAC) to find out more about how this technology could help shape the future of data center construction.

But first, the million-dollar question – what exactly is AM?

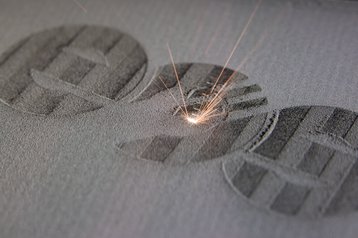

“Essentially, you’re talking about the creation of a physical product from a digital file. You start with a design as a CAD file and you make something by depositing material layer by layer, then sinter and you keep repeating the process until the object is complete.

So, basically, it’s 3D printing, right?

“Theoretically, 3D printing is a form of additive manufacturing – a subset if you like. When we talk about additive manufacturing, it means 3D printing on an industrial scale. People tend to use the two terms interchangeably. We don't call ourselves necessarily 3D printing, just because when people think about 3D printing, they tend to associate it with more consumer uses, smaller desktop types of machines, whereas additive tends to suggest an industry scale.”

With that cleared up, we move on to ask Mr Ho why this presents advantages over traditional manufacturing techniques.

“Well, the opposite is subtractive – where you start with a block of material and cut into the shape and scale of the final product you want, as opposed to additive, which is where you use exactly what you need to build exactly the design you want. That means, in additive manufacturing, you don’t require tools – it gives you more flexibility to customize the design, and then enables really complex designs that cannot be realized with traditional manufacturing.”

In other words, it allows you to design and build something from powdered materials, granule by granule, which would be extremely difficult to build with individual prefabricated parts. But the benefits don’t end there, as Ho explains, it offers bespoke scalability – both of the production run, and the premises.

“If you walked into a full-fledged car factory, that’s going to be pretty large – with AM you don’t necessarily need that level of space since the manufacturing technique gives you flexibility. You could have just a single machine or 10s of hundreds of machines, it's really up to the individual, the customers or the industry, depending on the output that they are looking for. One of the key advantages of additive is what we call distributed manufacturing. You do not need a large factory – if one machine was all you need, then I would say something like a small room would probably be enough to start off.”

If you’ve used a consumer 3D printer, you may be assuming that whatever the finished product, it will have to be made from plastic. But that simply isn’t the case – EOS can help you make what you want from a range of metals and polymers:

“We use a type of additive manufacturing which is known as powder bed fusion, and we have more than 20 types of metal alloys ranging from aluminum, nickel base stainless steels, steels, titanium alloys – all depending on the end application, the industry, and what our customers need. The other big group of materials are Polymers – polyamides, polystyrene, polypropylene and a whole host of other types. Now, obviously, as the industry is evolving, there are more and more interesting materials coming up in the near future, and all this is driven by our customer needs.”

If you need more convincing of the value of turning the manufacturing process on its head, look to the skies. With plans to colonize the Moon and even Mars in the coming years, AM will also allow pilgrims to print a new wrench in an environment where popping to the hardware store is out of the question. Which is all very cool – but let’s get to the rub, what can AM bring to the data center industry? The answer for Kei is simple – the sky's the limit – you tell us!:

“We always want to start with a problem that we're trying to solve. With the data center industry, I think there are many challenges that the industry is facing, like security, capacity, IoT. I think one of the biggest challenges is to be able to balance costs with efficiency, which essentially is the topic of energy efficiency.

“The amount of energy that data centers use is about one percent of global electricity needs, and that's a mind-boggling number. Then we have to ask ourselves, ‘Okay, what can a person contribute in order to make data centers more energy efficient? How do we reduce the environmental impact?’ How do we introduce new technologies that perhaps either aren’t available today or cannot be realized for certain reasons?”

But why stop there? Another EOS suggestion is to print the entire data center – in modular form, like giant Lego bricks. Transporting the means of manufacture to a remote location could prove to be a lot easier than delivering parts, tools, materials, and all the accompanying infrastructure.

“There's always going to be a need for huge data centers, but I think that a lot of places in the world where, either that investment is not necessary, or the space is a challenge and so maybe you don't need the hundreds of megawatts each time – start with a single module – a micro data center – and build out as you need.”

But what hopes do EOS have for their branching out into the world of data centers? At the heart of the answer, and at the heart of everything EOS does, is sustainability:

“Many data center stakeholders have never heard of, nor are they aware of what additive manufacturing can bring. They’ve probably heard of 3D printing, but they are not experts so it's for us to educate them in terms of what AM can bring.

“More important, is they can tell us what the problem is – and so often, it goes back to efficiency – how do we enable data centers to be more efficient? With traditional ways of cooling, that is really, really difficult, if not impossible to realize energy efficient data centers. So that's where we come in and advise and highlight some of the areas where we think AM could help you. We're not the data center experts, we need them to tell us in which areas they think they could save energy, and then we can come up with some suggestions.”

A perfect example of how AM can help comes in the form of EOS’s recent leak-free liquid cooled heat sinks, developed alongside CoolestDC – a cooling method that not only reduces water consumption, but also overall energy consumption, by as much as 45 percent, while improving center performance by up to 40 percent – all using a form factor that would be almost impossible to manufacture using conventional methods.

What else is EOS working on?

“Another project we are working on which relates to the data center industry is in increasing the efficiency of HVAC (heating, venting, air conditioning) systems. This project combines two levels of innovation in terms of product innovation in improved performance, and supply chain innovation in terms of digital spare parts warehousing. We envision that there will be significant energy savings through a complete redesign of key components which will enable weight savings along with complex geometries for tailored needs.”

And so, EOS has a challenge for you – imagine better – and then ask EOS how to make that a reality:

“What sets us apart is we are not about selling products, we're about selling solutions – it's not about selling machines, but rather, selling an end-to-end solution. We put it in those terms because it involves a lot of different things besides just the machine – a lot of knowledge transfer for example. Plus, we try to approach everything with sustainability as our guiding principle in everything we do.”

Kei and his team have high hopes for the future, and confidence at their ability to help data centers be cleaner, greener and more efficient:

“We are constantly evolving. We're constantly developing, we're constantly redesigning, to make things better and better and more and more efficient and that's definitely something we will continue to work on. I think we constantly have to evolve to innovate. I would like to see within the next five years that the benefits are proven, and have been deployed in data centers around the world on a large scale, because I think we really have to move fast to reduce power consumption, save energy and protect the environment.”

For more information about EOS, its offering for data centers, and its leak-free cooled heat sinks, click here