Specifying the power and cooling needs of even the most modest data center is never easy, regardless of whether it’s a budget focused public sector organization looking to add more servers than it can comfortably accommodate into a basement, or a hyperscaler with a big budget to kit out multiple halls.

Getting the right balance is superficially easy, but much harder when you’re the one on the ground.

Therefore, the kind of tool that can help spec out some of the most important equipment in the data center, automatically calculating cabinet size and numbers, and taking into account the server and other energy-consuming hardware, alongside the space available, could be a job saver as well as a time saver. In some instances, it could even save thousands of euros, dollars or pounds in recertification costs.

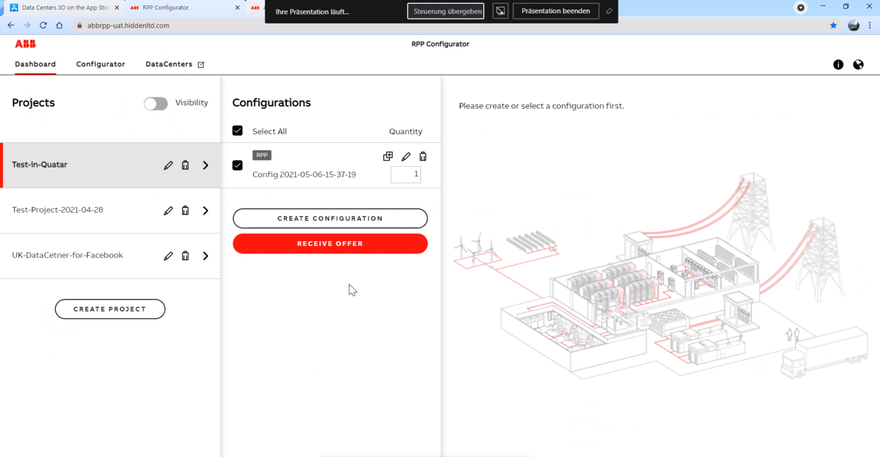

One of those tools is ABB’s Server Rooms Sub-Distribution Configurator, which ABB has recently upgraded.

“The Server Room Sub-Distribution Configurator enables consultants, electrical planners and all types of sales personnel to develop a high level configuration of power distribution solutions in the server room,” says Nico Ninov, market development manager, Data Center Server Room Solutions at ABB Switzerland.

One of the key benefits of using the configurator, is that it makes sure that everything adds up: that the equipment will fit into racks; racks will fit into rooms; and, the power equipment will comfortably serve the data center. The days of thumbing through 20 or more catalogs, comparing specs, circling product codes, and hoping it all fits together when the equipment arrives are over.

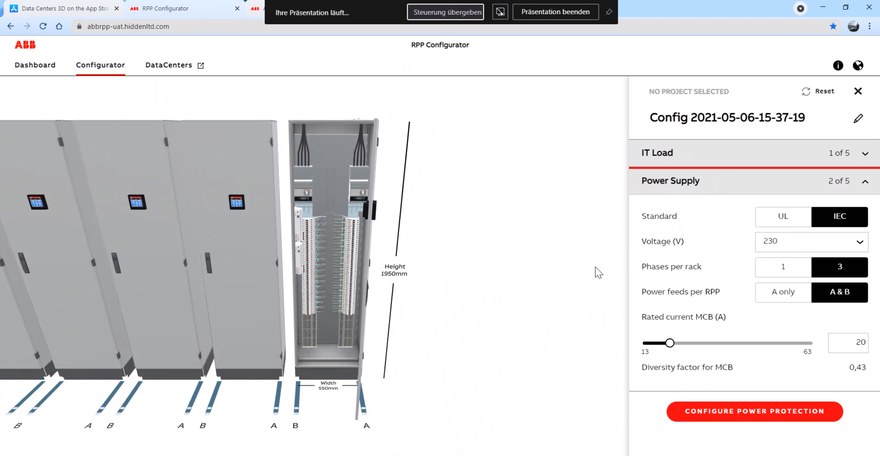

The configurator runs data center builders through a series of the usual considerations, including IT load, power supply, power protection, and monitoring. Crucially, at every stage it will display the exact equipment being considered, selected and configured, together with all critical specifications. This includes heights and widths, standards, voltages, wiring and so on – everything you need to know.

“It will show an overview of the data centre. And from there, people can deep dive and configure their power panels or their pathways. We call it the data center solutions portal, where you can access information about the different areas of the data center,” says Ninov.

He continues: “Let’s take the example of the remote power panel. You can see a virtual data center, and the remote power panels that supply servers on the other side of the data center room. When we design a remote power panel, we don’t have to perform a lot of technical things, just answer some simple questions that anyone who has ever created a data center ought to know.

“So, for example, the number of server racks planned for the server room and the average power per server. So, let’s say 300 server racks with good average values [wattages] per rack,” says Ninov.

The app is both highly visual and dynamic. Not only will it update the bill of materials as new data is entered, but it can provide an accurate visual representation of the goods. Users can see what they’re doing every step of the way.

“At ABB we put the right components together with a single line diagram with all the certificates that the panel builder needs, and send that package as a kind-of free of charge service to panel builders that can save costly recertification,” says Ninov.

“Recertification for a panel builder typically costs around €25,000. So, if the panel builder takes the design as we propose it from the configurator and builds according to those design guidelines, he doesn't have to spend 25k for this specific project,” he adds.

The app also takes into account the region where the data center will be operated – not just in terms of electrical systems and voltages, but also prevailing standards. And is flexible enough to consider the design preferences.

“Are the racks going to be single phase or three phase? This will immediately influence what we see in the 3D – one phase per rack will we mean a lot more cabinets; if we can fit three-phase devices in each cabinet then we’ll need fewer cabinets in total,” says Ninov.

“There’s also some optimization based on ‘decision steps’ that the client can make… there are a couple of questions around power protection, whether that should be inside or outside the power panel, which depends on whether the designers prefer to design the electrical distribution with or without mains protection in the cabinet.

“Some prefer to have it externally, then they're just installed in the normal power panel outside the Remote Power Panel. Some prefer to put it right in the RPP cabinet.” says Ninov.

The resulting designs and bill of materials are securely saved in the cloud, rather than locally, and can be shared among everyone in the project team, as necessary. Furthermore, when the time comes to order the equipment it can be forwarded to the appropriate distribution partner or directly from ABB.

There are many more features to explore. It is now available from the Apple Store for iPad, can also be road-tested here.

More...

-

Sponsored ABB solutions power Europe’s greenest data center in Norway

With ABB technology Lefdal Mine Datacenter plans to become Europe’s biggest, with the smallest environmental footprint.

-

Operators need better visibility from main distribution down to the server for better predictive maintenance, says ABB’s Nico Ninov

“Deep component visibility down to the chip” the key to better power consumption, maintenance and reliability, claims Ninov

-

ABB invests £3.25m into hydrogen power company AFC Energy, plans data center partnership

Will pitch AFC fuel cells for data center deployments