Despite the increasing popularity of Lithium-ion battery technology, valve-regulated lead acid (VRLA) batteries remain the most widely used in data center UPSs today. However, they must be managed with a suitable battery monitoring strategy to maximise their operational life, and to ensure adverse environmental or operational conditions are detected and corrected before battery damage occurs.

Valve-regulated lead acid (VRLA) batteries maintain their dominant position because they are still regarded as the safest, most reliable and cost-effective technology for most applications.

However, their reliability depends on being operated within a suitable environment, and maintained correctly throughout their working life. Accordingly, it makes sense for a UPS owner to either set up a battery monitoring system, or employ a third party such as their UPS supplier to provide a remote battery monitoring service.

This will reduce or eliminate the possibility of the battery failing when the UPS needs it, while also optimising battery operational life.

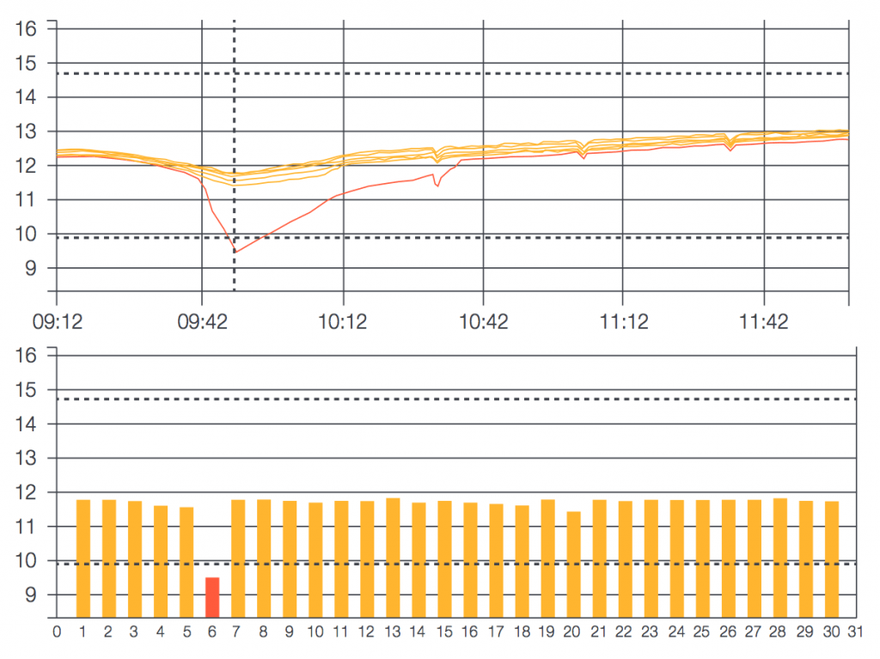

UPS Ltd’s PowerNSURE, for example, is a web-based service that checks the internal resistance, temperature and voltage of every individual battery sequentially. It can correct equalisation problems arising when individual batteries take differing charges, by adjusting the charging voltage across the entire battery string as necessary. Proper equalisation prevents undercharging and associated problems of sulphation and loss of capacity.

Monitoring offers other benefits, too. By spotting overcharging, it prevents gassing, dry-out, thermal runaway and corrosion. Trends in resistance testing results can provide early warning of damaged or weakened battery blocks. This allows timely replacement of battery units, which improves the complete battery system’s lifetime. In any case, equalising extends service lifetime by up to 30% through keeping all batteries constantly within their ideal voltage window, all negative influences due to incorrect charging voltages and currents within the string are eliminated.

A monitoring system will typically display the battery status, and record any changes to resistance, temperature or voltage. Through constant monitoring on user interfaces, and regular report generation, operators can optimise battery performance and reliability. We can summarise the benefits of battery monitoring as below:

- Extends battery life by equalisation

- Monitors and regulates the battery charging process and avoids under-charging

- Indicates battery problems before failure

- Monitors condition of every battery individually including temperature

Alan Luscombe is marketing director at Uninterruptible Power Supplies Ltd