I’m sure most people are familiar with the fairy tale of Goldilocks and the Three Bears.

While the version likely heard as a child may vary a little, the basic premise is that Goldilocks finds a house in the woods where she tries some porridge, sits on numerous chairs, and tests out a variety of beds, before finding the perfect version of each.

I’m here to tell you that this reading of the tale has it all wrong. It isn’t that the items were too hard or too soft, or that the porridge was too sweet or too salty—it is actually that each one is perfect as it is because it matches the characteristics, size, and prioritized needs of its owner - ie Daddy Bear, Mummy Bear, or Baby Bear.

Those same principles also apply when it comes to designing and building data centers. The process of identifying which challenges to prioritize and how much of the design should be productized will be project-specific and ultimately drive project size based on the choices made.

There is no one-size-fits-all solution. There are instead design approaches that fit the scale and type of data center you desire to build.

Priorities drive productization options

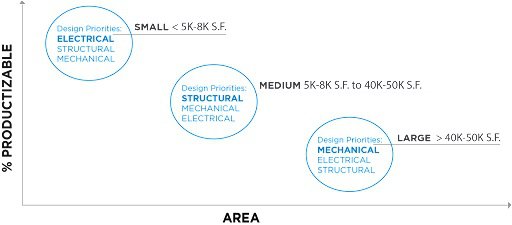

Experience shows us that priorities shift from smaller edge designs, through mid-size core and shell projects, to large, hyperscale data centers. With the shift in priorities, the ability to productize design also shifts (see diagram below). What drives those shifts and how to prioritize design options are the central questions in this piece on modularizing data center builds.

The starting point when thinking about design priorities is to start with the three biggest design areas – electrical systems, mechanical systems, and structural design.

While there are other elements in a data center design, these three provide the core of any design, and resolving them first makes choices in the remaining areas much simpler.

However, the order of priority between these three core elements varies significantly depending on the size of the project undertaken.

The key with each size group is to identify what problem to solve first and what order the others follow to provide the most efficient design approach.

Our experience suggests that the most effective approach is to prioritize in order of which element provides the biggest challenge or presents the greatest limiting factor for the data center size being built.

Starting off small: <5K sq. ft.

Starting at the smallest data center project size, the initial problem that needs to be solved involves electrical systems and related design constraints.

The UL and National Electrical Code are very proscriptive. For example, in a certain voltage class, there are minimum live-to-live distances and minimum live-to-ground distances.

Add these requirements to the sizes of key equipment needed and the compounded dimensions really start to matter—especially in small-scale spaces.

As a percentage of space in small data centers, electrical components end up being the majority of the mass or volume captured. This is why it’s critical to focus on electrical system design choices first so that the foundation is set for the rest of the design.

In small-scale builds, the next priority is the structural system. Impactful decisions to be made: what is needed out of the structural system? Does the build need to be phased? Should the project be built as a core and shell building or should the structural system be freestanding? Where will the build be deployed—what geographies? The answers to all these questions help drive the appropriate solution and can lead in very different directions.

Despite their strategic importance, at this scale, mechanical systems are the last in line. Fundamentally, the main mechanical systems challenge surrounds rejecting heat from a heat source to ambient. In a small, containerized solution it may be only five feet from one to the other.

The short distances involved likely means any preferred mechanical solution can integrate and align with the electrical and structural priorities that were already set.

More questions at medium scale: 5K-50K sq. ft.

As size increases, the constraints placed on design priorities by electrical codes start to fall away. Instead, structural considerations rise to the top to dominate design decisions.

The questions asked around smaller projects are still relevant at this size. In particular, whether there is a need to build with a volumized approach or if it makes more sense to build a core and shell building?

Whatever the answer, another important consideration is whether the design should be productized or highly customized for a one-time deployment?

As a result of the increased volumes of this size build, mechanical systems come next in priority. The increased size of the facility means significantly increased distances from the source of heat loads to ambient – in a 40,000 sq. ft. facility that distance may increase to 200 feet.

As such, the challenges of designing an effective system increase, as do the levels of sophistication of the methods needed to achieve the necessary impact.

In comparison, while there are design decisions to be made around the electrical systems, those problems become very discreet at this size.

Larger data centers need different considerations: 30K-50K+ sq. ft.

As projects grow to large data center sizes, mechanical systems rise to the top as the most important design consideration.

The issues identified above around the distance from the load to the ambient get to the point where they become the biggest problem that needs to be solved first.

With increased size, the amount of heat that needs to be moved requires a bigger heat rejection system. This means that major design decisions about how to get the cooling plant to work – how to cover large distances, how to manage the mechanical systems efficiently to minimize heat loss, etc.— matter greatly. At large scale, mechanical systems are the engine driving everything else related to design.

Similarly, at large scales, electrical systems rise back up the priority list. With the increased cost of electric cabling and equipment, working out how to efficiently manage these expensive commodities, while dealing with large spans, provides an important challenge.

Finally, at this scale, structural choices become relatively straightforward and are largely defined by the decisions initially made around mechanical and electrical.

Productization can be attractive

One of the reasons a modular construction approach is attractive is because it offers the ability to productize elements of a design. As with other decisions based on build size, productization can be an attractive option in the right setting. While productization is always achievable, the important question to ask is whether it’s advisable.

The key is to not go into the process with a decision already fixed around what will and won’t be productized. Instead, let the design priorities guide what to productize.

The process described previously of separating and distinguishing various elements helps make those decisions much more apparent. Our experience suggests that, in most cases, the portion of a project that will benefit from productization generally reduces as project sizes increase. But that isn’t always the case, so let the project be the guide.

In practical terms, it’s important to bring all of the project’s stakeholders into the process so that critical decisions are considered holistically and any potential impacts are taken into consideration.

Prioritization is key to a happy solution

With rigorous prioritization that aligns with the size of the data center project, the challenges of creating an effective design for your next data center modular build can be significantly reduced.

In our version of the Goldilocks story, everyone can find the porridge, chair, and bed that fits their needs to live happily ever after.