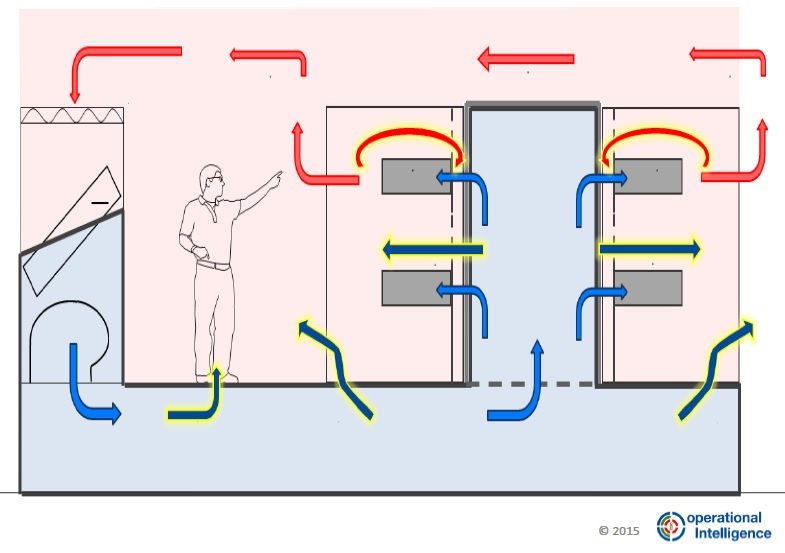

The objective of containment is to segregate the hot and cold air streams, to minimise recirculation (exhaust IT equipment hot air re-entering intake) and bypass (cooled CRAH air not making it to IT equipment and returning directly to the cooling units). There are two fundamental issues: firstly, even with a perfect containment system, the amount of air supplied needs to be controlled to satisfy all IT equipment requirements, and secondly, containment is only part of the segregation solution.

There is a very simple way to check if there is enough cold air being supplied. In the case of cold aisle containment, open the cold aisle door slightly and verify the air flow direction with a sheet of paper. If air is coming out of the cold aisle, there is a slight oversupply of air to the cold aisle (which is fine), however, in many cases hot air is entering the cold aisle, which means that there is insufficient air supplied, making recirculation inside the cold aisle inevitable.

This can be due to incorrect type and number of floor tiles or simply insufficient air volume from the CRAHs. There are some very simple and rapid methods / metrics to diagnose air management based on temperatures, etc. such as Af (Availability of flow) which is the ratio of CRAH air volume to IT equipment air volume. Normally a slight oversupply of air (with a small amount of bypass) is better than undersupply (which causes recirculation). A large oversupply of air is an energy opportunity, whereas a large undersupply of air will inevitably lead to considerable hot spots.

The next concern is the quality of segregation between hot and cold air streams. The metric defined as Air Segregation Efficiency = 100% (ideal) when there is zero bypass and zero recirculation. The important concept here is that we are trying to create a physical barrier between the cold and hot air streams, for which we use a containment system. Most containment systems (excluding butchers curtains) are very hermetic. The issue is regarding the other segregation areas which are not part to the containment system, such as the raised floor where you can have unsealed cable cut-outs and floor grilles in the hot aisles or the front of the rack where there is a lack of blanking panels between IT equipment and gaps at the sides.

Whilst I am all for containment, the reasons why it is being installed need to be fully understood and monitored in order for its objectives to be met.