Unprecedented demand for increased bandwidth is driving the deployment of high fiber count ribbon cables with multi-fiber push-on (MPO) connectors.

These cables are used in hyperscale networks to provide campus and metro connectivity between individual data centers and Edge compute deployments in support of low latency 5G network applications.

Owners and operators of these networks rely on a vast base of contractors to support the test and turn-up of these links. There is a strong case to be made for the use of multi-functional instruments and test process automation (TPA) during data center construction and commissioning.

Proven to enhance testing quality and consistency, increase resource utilization (financial and human), and reduce overall cost, this novel approach achieves faster deployment and monetization of data center networks comprised of high fiber count MPO cables.

Let’s build the case by taking a closer look.

Challenge 1: Lack of expertize

Since legacy data centers used mostly single-fiber or duplex connectors, such as SC or LC, even experienced data center contractor technicians often lack the expertize required to quickly, accurately and cost-effectively test high-fiber-count ribbon MPO cables.

While Tier I tests are the same – measure length and optical loss, check polarity and ensure endface condition – the process of MPO cables is more complex, more time-consuming and therefore more costly.

Challenge 2: Prevalence of legacy equipment

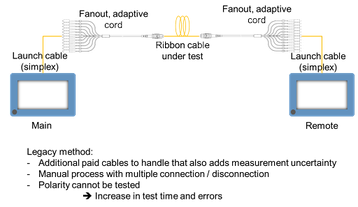

Many of the challenges that technicians encounter when testing MPO connectors result from using tools designed for testing single-fiber connectors.

Using single-fiber legacy test devices on MPO networks requires adaptive equipment – adding time, complexity and cost to the test process as shown in Figure 1.

For example, an Optical Loss Test Set (OLTS) can be used to measure length, insertion loss and optical return loss and check the continuity of MPO links with the addition of fan out cables that break the MPO down to individual LC or SC connectors.

However, this adds significant complexity and costs (expensive cable fan out assemblies) to the process.

Challenge 3: Turn-up urgency

Contractors are often charged with scaling up a network in the shortest time frame possible in order to quickly turn-up and monetize the data center.

This urgency often results in the decision to reduce testing timeframes and the number of tests performed and recorded. This is despite data that reducing the number of tests can negatively impact testing accuracy where averaging results is critical to the testing process.

For example, averaging results in Tier II Optical Time Domain Reflectometer (OTDR) testing is imperative to reduce the noise level enough to identify passive elements such as splices and provide a more accurate measurement of loss value.

Reducing the number of tests reduces averaging, which may result in missing events and invalid results being recorded in the network management database.

Challenge 4: Increasing fiber counts

In hyperscale data centers and 5G networks, current fiber counts can be as high as 6,912 and even higher-count fibers are being manufactured.

Testing a cable of this high-fiber-count using adapted legacy single-fiber test equipment could take contractors weeks if not months, plus the time to manually/visually audit all the recorded test results.

Challenge 5: Network database visibility

As noted earlier, the time to test high fiber count cables takes an equal amount of time to manually/visually audit and store all the recorded test results, providing an equal amount of opportunity for more human error.

How qualification test results are labeled and stored also impacts their utility when data extraction for visibility into network connectivity is required.

Addressing challenges using bi-directional testing

In addition to test averaging, bi-directional testing is required by industry standards and for manufacturer warranties, adding more time to the testing process.

The need for the fastest testing and qualification process makes bi-directional testing vital to maintaining MPO connectivity visibility into the Data Center Interconnects (DCIs) that form the longer external data pipelines connecting data centers on hyperscale data center campuses (Access Networks) and Edge data centers across a larger geographical area (Metro Networks).

Not only is bi-directional testing faster, but it is also more accurate, removing uncertainty from impairments difficult to identify in the fiber span. Only bi-directional testing gives a true loss value, which is critical to tight budget and higher transmission networks.

In fact, bi-directional testing is the recommended method for accurate loss measurement per IEC Standards 62316 and 60793-1-40 and TIA Standard FOTP61, which state:

“Splice and attenuation measurements with an OTDR must be conducted from both directions and averaged for accuracy to eliminate the effects of backscatter differences, also referred to as gainers and exaggerated losses.”

Summary

The lack of MPO testing expertize, prevalence of legacy test equipment, increased process complexity, urgency to turn-up and ever-increasing fiber counts all increase the opportunity for human miscommunication and error during the MPO testing and qualification process.

Each of these challenges increase the likelihood of future site visits and retesting, adding to commissioning costs long after this phase of the project has ended and further delay data center monetization.

While onboarding technicians are doing all that is humanly possible to overcome MPO testing challenges, the need to speed the process, maintain accuracy and reduce the opportunity for human error makes clear the need to fully automate the MPO testing process.

This is possible using purpose-built multi-functional equipment that intuitively guides the contractor through the different steps of the testing process, manages bi-directional testing and fully automates the acceptance and reporting process for high-fiber-count ribbon MPO cables.

VIAVI Solutions FiberComplete PRO adds to the innovative line of FiberComplete products, reducinh testing time by up to 80 percent. To learn more, please click here.

More from VIAVI Solutions

-

Sponsored Hyperscale ecosystems: Factory automation and the industrial IoT

Viavi CTO Sameh Yamany examines the elements behind the industrial IoT and how hyperscale data center ecosystems will support it

-

Sponsored VIAVI unveils FiberComplete PRO

Automations, integrated datalink and one button operation reduce testing time by up to 80 percent

-

Sponsored VIAVI adds 400G performance to OneAdvisor 800 field testers

VIAVI’s modular handheld instrument offers the first full-capability, single-box solution for modern network field technicians

-

Sponsored Hyperscale use case: Advanced Driver-Assistance Systems (ADAS)

Could Advanced Driver-Assistance Systems (ADAS) be the push needed toward a fully autonomous future?