Looking for alternative fuel sources that are reliable can lead one to weird places. That was the case for Microsoft, whose search for fuel that was reliably available where its user base is (all over the planet) led it to places most reliably present almost anywhere there were concentrations of humans: dumps, fuel refineries and wastewater treatment plants. The thing they all have in common is they all generate gaseous byproducts, collectively referred to as “biogases”, which fuel cells can turn into energy.

Using fuel cells to convert gas into electricity to power a data center is nothing new. Integrating a data center with one of the aforementioned human necessities and unplugging it completely from the electrical-utility grid in favor of powering IT entirely by processing biogas, however, is a radical idea, and one Microsoft’s data center team is about to try out.

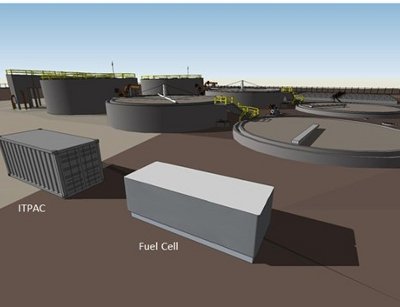

The company is going to install one of its data center modules, called “ITPACs”, at the site of a wastewater treatment facility in Cheyenne, Wyoming. As we reported earlier this month, a state economic-development agency recently approved a US$1.5m grant for the city to build infrastructure for the project. On Monday, Microsoft revealed more details about its first live test of the “Data Plant” concept it has been talking about publicly since 2011.

Brian Janous, the company’s data center utility architect, says strategically, the project is an “opportunity to demonstrate a concept we can then prove out at scale, as we go across the globe.” If the experiment in Wyoming is successful, Microsoft will be able to “go globally, where we have customer demand, and utilize what we see as a wasted energy resource.”

As mentioned before, the concept of biogas as a fuel source is nothing new, and the reason it is not commonly done is that the process to convert it to energy and feed it into the utility grid is uneconomical. Data centers – and especially small data center modules – offer a unique opportunity because they can be placed directly at the source.

Microsoft’s pilot ITPAC in Cheyenne will use up to 200kW, or 100kW less than the total output of the fuel cell powering it, Sean James, senior research program manager at Microsoft, says. The rest will be used by the wastewater treatment plant to help power the treatment process. According to the team’s estimates, the fuel cell will take a big bite out of the total amount of biogas the plant creates. “Essentially, we’ll be consuming about three quarters of the biogas that’s being produced today,” he says.

Load management is key to success

They know how much power the IT is going to need at peak load, and they know how much electricity the cell will be able to produce at peak load. What they’re really testing is the load-management mechanism between the data center, the fuel cell and the water treatment plant. Fuel cells are known to respond slowly to changes in load, and the load-management system needs to make sure the energy supply can respond quickly enough to these spikes and dips, James says.

If there is a spike, valves that control the flow of gas need to open quickly to accommodate the demand. If there is a dip in IT power need, the valves need to respond by closing. The load-management system uses ultracapacitors to maintain a steady load while the valves are opening, and uses load banks to store unused energy while the valves are closing or sends it to be used by water-treatment equipment.

Biogas fuel cells are only one of the alternative on-site data center energy sources Microsoft is looking at. Another option, at least in the US, is natural gas, whose cost in the country is really low, thanks to hydraulic fracturing. “We’re quite interested in natural gas as well, particularly in the US when there is such a glut,” Janous says. There are no fuel cells using natural gas to generate electricity at any Microsoft data centers today, he says, but “it’s something that we’re definitely investigating.”