Hydrogen and its derivatives have been a hot topic in the data center industry for a while now, with more than one key player already adopting it as a secondary energy source to act as a back-up to the electrical grid.

Engie has committed significant resources to researching and bringing new technologies to market for the production, distribution and storage of green hydrogen and, just as importantly, its derivatives such as methanol, ammonia and e-kerosene, as well as biofuels. This will allow the company to be at the forefront of the zero-carbon fuel chain.

Red Engineering has worked in conjunction with Engie to establish a new, flexible and future-proofed design for data center energy infrastructure, which will update power and cooling generation systems to accept these new fuels as they come to market, transforming them into primary drivers for the zero-carbon transition.

Indeed, low-carbon and even renewable hydrogen-based solutions are key strategic elements of Engie’s support for heavy mobility and industrial players who are looking to achieve their carbon neutrality objectives. By 2030, Engie plans to develop a green hydrogen production process capable of capacities of four gigawatts, with 700km of dedicated hydrogen networks, one terawatt hour of storage capacity, and management of more than 100 refueling stations.

None of this has happened overnight, of course. As long as five years ago, Engie was already working on innovative pilot projects. Now, the company is ready to target large-scale projects with concrete achievements in mind, with 70 projects of between 20 and 50 megawatts already underway, in addition to 50+ projects of up to 50 megawatts. In all cases, Engie acts as a developer, integrator and operator across the entire hydrogen value chain: production, distribution, storage, gas to power and beyond.

When it comes to options for data centers, different types of technologies using hydrogen and its derivatives are available, enabling everything from backup solutions to primary energy sources of electricity. There are two main ways to generate power this way – fuel cells and turbines.

The path towards zero-carbon is paved with challenges

Let’s start with fuel cells. There are already pilot projects alive and kicking around the world, so we have a large data set on which to base our analyses, which will help us judge just how viable hydrogen based solutions can be.

They are six types of hydrogen fuel cells, with their performance depending on chemical potential. The two most promising options for powering data centers are PEMFC (Proton Exchange Membrane Fuel Cell), delivering between 100 watts and one megawatt, and SOFC (Solid Oxide Fuel Cell) ranging from one kilowatt to 100s of megawatts. PEMFC is ideal for secondary power back up or primary production, while SOFC should be used for primary production only.

Compared to an on-grid solution, hydrogen fuel cells bring high efficiency and reliability, low to zero carbon emissions, minimal maintenance requirements, and modularity. Depending on the way they are used, fuel cells can save money that would be otherwise spent on diesel generator backup and on the power grid for the data center. But on the other hand, as a relatively immature technology, hydrogen comes with concerns, many related to the underdeveloped supply chain, such as safety – after all, hydrogen is a flammable gas.

Added to that, there are considerations of footprint and weight, high initial cost, and even local legislation which may not be well defined. The physical footprint of fuel cells is particularly challenging, as hydrogen fuel cells require large amounts of surface area, which can be difficult to come by in the case of data centers located in urban or suburban areas.

Transportation and storage of hydrogen are also key considerations. The main storage options presently being considered are gaseous H2, liquid H2 or ammonia, each with their own pros (purity, power range) and cons (conversion losses, toxicity, footprint). When you add transport logistics between the hydrogen production site and the data center, you also have to consider the limitations of each of the methods of transportation: usually meaning pipelines for high pressure gaseous hydrogen, while road, rail and sea routes would normally use low temperature liquid hydrogen.

Let’s look at a case study from Engie and Red, which forms part of our Green Data Center Research and Innovation program. In this case, we’re looking for a fuel cell backup solution for a data center of five megawatts, with twelve hours of stored H2 on site, totalling around five tons of hydrogen.

To store this amount of hydrogen, no less than three cryo-vessel storage vessels added to 10 cylindrical portable storage vessels are needed, requiring a large footprint of well over 350 square meters.

Health, safety and security are particularly significant considerations, where the use of hydrogen is subject to well-defined codes and standards. Safety alone is dependent on five key points:

- Identification of hazards and appropriate mitigation measures

- Ensuring system integrity

- Prevention of any gas accumulation, using proper ventilation

- Leak detection and isolation

- Adequate training of personnel

Engie’s studies compare the Total Cost of Ownership (TCO) between H2 fuel cells against diesel generators, leading us to conclude that while fuel cells are a very efficient method of using hydrogen to produce electricity, due to land area constraints, they are more applicable to lower yield solutions.

In one of our studies for a six megawatt data center, the TCO for a hydrogen solution was still over twice that calculated for diesel gen-sets, with the additional cost coming from storage vessels, as well as health and safety compliance.

The price-gap between the two solutions will narrow in the coming years, but there are currently no solutions where hydrogen backup solutions would be cheaper than a diesel based solution by 2030, a key date in the world’s decarbonization plans.

Is hydrogen a dead-end for data center applications ?

Alternatives to fuel cells already exist. Gas engines and gas turbines have been in use since the beginning of the 20th century, but at that time, they were huge, bulky, low-speed machines – nothing like the modern agile and flexible units of today.

Work started in the 1980s to produce the efficient gas solutions of today, yet until quite recently gas engines and turbines had major flaws for data center applications including long start-up times, low turndowns for low-load configurations, large footprints, limited power output, and so on.

In recent years, huge progress has been made by Engie’s Research and Innovation Department to find new solutions to address the increasingly volatile electricity market, working closely with equipment vendors to improve the flexibility of all power generation technologies. For instance, you can now find gas turbines on the market ranging from one to 40 megawatts with very acceptable footprints.

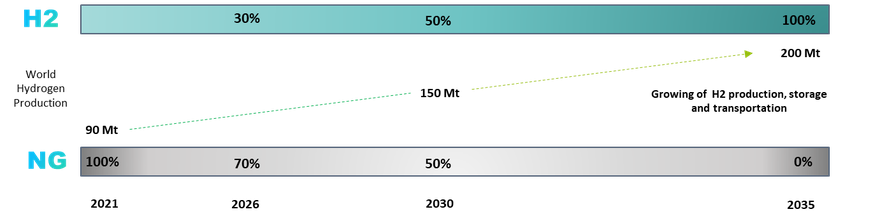

Moreover, today many gas turbines and gas engines are capable of running on mixed fuels. Even though, for now at least, natural gas remains the main fuel, hydrogen and derivatives, as well as other green fuels such as biogas can already form a significant share of the fuel mix.

In the future, gas engines and turbine generators will be able to accept an increasing blend of these green fuels, with the ultimate aim of running on 100 percent green fuels as supply chains develop. Gas turbines, in this respect, appear to be far more flexible in accepting different fuels and we believe that these will become the preferred choice for zero carbon decentralized generation moving forward.

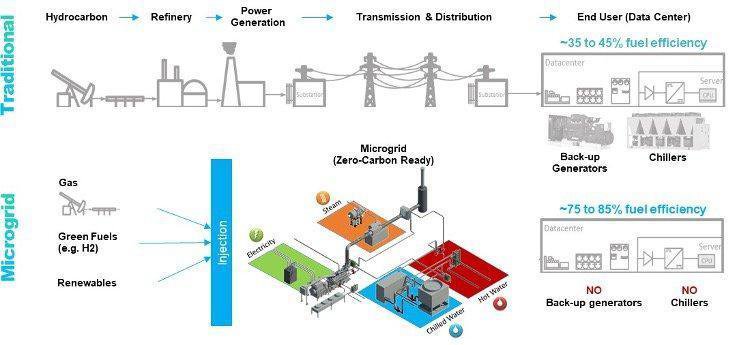

That said, if a data center has an on-site power generation capability that can be operated continuously, running on an affordable mix of fuels with a very low emissions footprint, then it may very well be used as a primary source of power. Designed with capacity redundancy and concurrent maintainability to ensure that sufficient capacity to cover the data center’s maximum load is always available, such a plant would be able to provide a power supply without interruptions, even during the maintenance of individual equipment. This approach reverses the traditional way of operating the data center energy source, where the on-site power plant becomes the primary source of electricity, and the public grid acts as a backup.

Engie and Red provide multiple simulations for demonstration, showing different power and cooling scenarios to assess the reliability of systems as well as providing inputs for the techno-economic analyses, to assess the running costs, capital costs and CO2 / NOx emissions across the year. The selected optimum solution from these analyses will be used as the basis of concept designs for microgrids and accompanying energy centers.

A highly efficient energy solution enabling the data centers’ decarbonization pathway and guaranteeing high availability

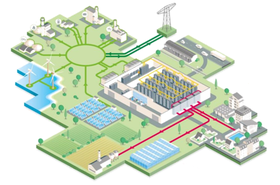

A new energy model like the ones we’ve been talking about, is dependent on the creation of a microgrid, embedding on-site power generation via mixed-fuel gas turbines, with the possibility of complimentary on-site renewable power generation (e.g. solar PV) and storage. This array tends to be more and more competitive compared to the traditional data center energy design.

The flexibility in the quantity of gas turbines installed on-site enables operators to align the generation capacity with the data center IT load ramp-up, avoiding undersizing as well as oversizing of the on-site power plant and systems.

In the case of rapid expansion of the IT load, modular on-site generation capacity is key to rapidly ensuring a sufficient power supply, allowing the data center to become independent of the public grid power supply and avoiding overloading of the network.

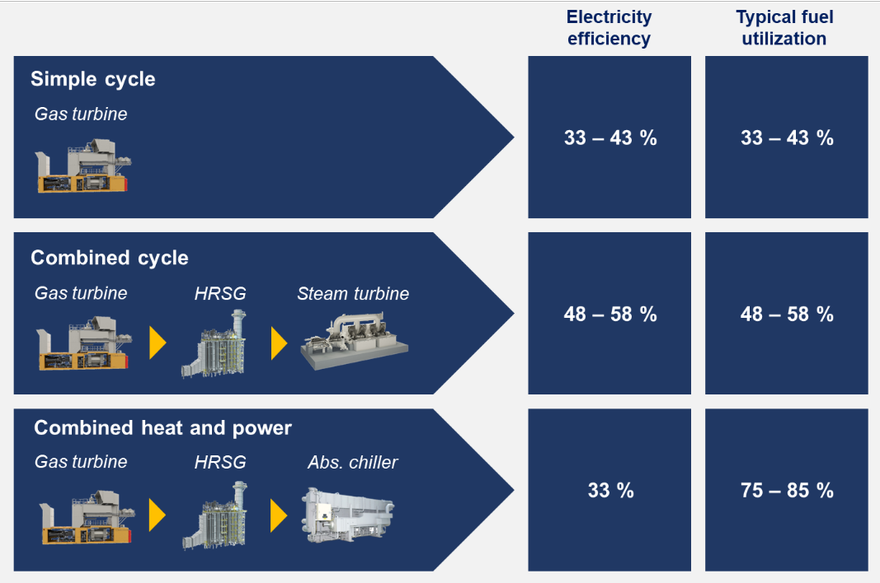

When it comes to lowering the emissions of data center activities, energy efficiency is obviously a key topic to address. The most basic set-up for power generation is the open cycle power plant, which consists of a gas turbine powered by a fuel that is converted to thermal energy and mechanical energy to drive a generator to produce electricity.

The big disadvantage of this basic configuration is that thermal energy is exhausted as waste heat. Combined Cycle technology makes it possible to put this waste energy to further use by using the waste heat from the gas turbine to produce steam in a heat recovery steam generator (HRSG) which, in turn, powers a steam turbine, thus increasing electrical efficiency. This effective design requires slightly more space, but generates the highest amount of electricity from the combustion of fuel in the process. Efficient, yes – but we can go even further.

Further ways exist to use the waste heat from the gas turbine combustion process. Following the HRSG, the waste heat can be transferred to an absorption chiller to also serve the cooling needs of the data center.

This new approach to waste energy has turned out to be far more efficient than traditional designs (primary power from the electricity grid and diesel back-up generators on-site), drastically reducing the amount of net energy losses.

In terms of economics, an equivalent (or even better) Total Cost of Ownership can be achieved compared to a traditional data center design (over 15 years – a typical lifetime for a data center). Meanwhile, decarbonization efforts can take place through the use of green fuels such as hydrogen. Indeed, a high CAPEX can be expected due to the energy plant and systems which are part of the local microgrid, but, for a very diverse range of different geographies, lower OPEX figures will be observed, especially concerning the price of energy (power and cooling).

Moreover, such an energy concept enables data centers to generate new revenues by reselling the surplus of waste heat being rejected, any surplus of cooling produced on-site, and participating in grid stabilization services (demand side reduction/firm frequency response etc). In the case of a completely off-grid project, significant enabling costs can be eliminated such as grid connection works – these can easily raise up to several million euros – as well as associated taxes.

H2-ready project showing positive sustainable impact

Recent studies led by Engie and Red have focused on a new Middle East data center project where the energy assets’ design needed to overcome limits of the national grid capacity, reliability limitations and water scarcity, whilst having the ambition to deliver the greenest data center in the region.

To achieve this, Engie and Red are designing and will ultimately install high resilience power and cooling services (minimum Uptime Tier III) outsourced from the data center, which will be low-carbon ready and future-proofed to accept technologies to drive it to carbon neutrality within five-10 years.

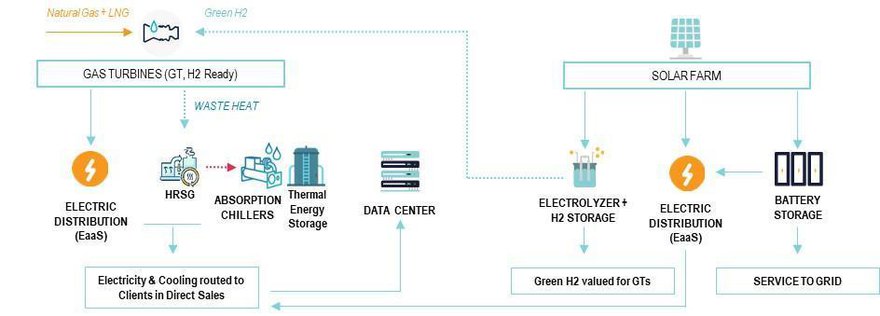

This innovative energy concept involves hydrogen-ready gas turbines, heat recovery steam generators to distribute the gas turbines’ waste heat to absorption chillers to locally produce cooling, as well as a solar farm that will, step-by-step, provide both electricity directly to the data center itself and to an electrolyser in order to produce green hydrogen that will increasingly be used as the main fuel for the gas turbines.

Obviously, reaching this zero-carbon ambition cannot happen on day one and needs to be part of a decarbonation roadmap that takes into account the availability of hydrogen-based fuels (production, transportation, storage and distribution) in order to fully cover data center power needs.

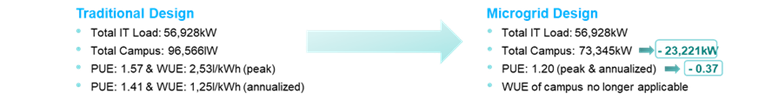

The combined solution of gas turbines and absorption chillers allows us to achieve better power efficiency (PUE) and water efficiency (WUE), even within the local harsh environmental conditions.

This energy model not only shows sustainability benefits. Outsourcing all energy production to a decentralized generation plant (the “energy center”) on-site, containing all items of power, heat, and cooling generation, allows for ease of maintenance and operational control.

Moreover, it is also a way to drastically optimize the IT space within the boundaries of the data center, since all back-up generating and cooling facilities no longer need to be located within the boundaries of the data center site. In fact, the current design stage shows a potential of 66.7 percent increase in IT space.

All of this is achieved in compliance with the specific uptime requirements for the data center. As part of the on-site energy center owned by Engie, the high availability of power and cooling is secured by becoming independent of national grid fluctuations and by combining multiple fuels, different generation equipment and thermal/electrical storage, thus creating the proper conditions for high availability as required by any mission critical building.

Conclusion

Fuel cells are hugely efficient methods of using hydrogen to produce electricity, but due to their related transportation, storage and land constraints, are more applicable to solutions of only a few megawatts. Even by Engie’s and Red’s most optimistic estimated scenarios, by 2030, their costs will still be twice as high as diesel genset solutions.

Therefore, when it comes to continuous power and heat generation for large applications (above 10 megawatts), multi-fuel turbines and combustion engines are the best solutions. Already proven technologies, they are capable of showing high fuel efficiency in trigeneration mode, when properly installed and operated by energy specialists, whilst fulfilling the power and cooling needs of the data center at the same time.

More from Engie

-

DCD>Talks the APAC Market with Wandrille Doucerain, Engie and Phil Reid, Red Engineering

In this DCD>Talk we discuss the future of the data center market in the Asia Pacific region with Red Engineering and Engie

-

Sponsored How do data centers provide low-cost, zero-carbon energy to local communities?

An introduction to waste heat export in supporting local communities

-

Sponsored Microgrids and data centers: How to increase high availability while achieving decarbonization objectives

The N+K microgrid can provide an effective alternative to the traditional N+1 or 2N resiliency. Here’s how it works