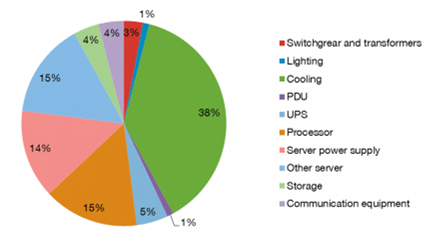

Data centers are known to be high consumers of electric energy, with the cooling processes necessary to maintain IT rooms at the correct temperatures often accounting for more than a third of a facility’s total electrical energy demand. This, of course, does not come cheap.

Assessing energy use and efficiency is therefore crucial and achieved by measuring metrics such as Power Usage Efficiency (PUE) – referring to the ratio of total facility power to IT equipment power. The past 15 years have witnessed the average PUE of data centers around the world going from 2.5 to 1.6, with new build data centers capable of reaching 1.2 in some regions.

For some time, PUE has been considered a key metric in the data center industry, and is often relied upon as a way to prove the sustainability of a facility. But as the onus on greener facilities continues to grow, and electrical energy efficiencies become harder to achieve, Water Usage Effectiveness (WUE) – PUE’s little brother when it comes to the efficiency of water consumption – has become the new hot topic.

Indeed, the data center industry and authorities, alongside the general public, have started to take notice of the amount of water many facilities are using to prevent them from overheating. Cooling systems also often involve water that is evaporated in cooling towers, leaving behind wastewater known as blowdown that has to be treated by local utilities.

Furthermore, as computing capacity continues to increase at the same rate climate change is exacerbating drought – particularly in water scarce regions – the huge amounts of this precious resource needed to keep a data center cool simply isn’t sustainable.

This begs the question: is it possible to remove water from data center cooling processes? The short answer is yes. Through a combination of RED’s engineering capabilities and Engie’s energy solutions, a data center can drastically reduce its water use or even eliminate it from the cooling process altogether.

Reduction of water usage in cooling process

IT equipment converts the electrical energy powering it into thermal energy. This is why data centers, which are basically warehouses containing thousands of machines, need to be able to remove this heat to maintain acceptable operating conditions.

To do this, several solutions exist, for example, collecting the heat for other uses, using energy-intensive cooling technologies, and/or relying on water to bring the temperature down, notably via evaporation.

In some regions where the climate allows, low-energy and -water demanding alternatives exist, such as free cooling / free chilling. That said, even in these locations, water is usually still required to operate energy- or water-intensive technologies at certain times of the year, when the outside climate conditions can no longer maintain acceptable operating temperatures.

When it comes to selecting the best fit cooling technology for a particular facility, this should be evaluated on a case by case basis, not only in relation to geography, but the way the business operates. At some facilities for instance, it may be more water-efficient to consume water onsite due to a more water-intensive supply chain.

However, this doesn’t take into account the current transition to solar and wind power, meaning the water intensity of electricity production is slowly moving toward an all-time low. Therefore, in the long run, the data center industry will no longer be able to justify consuming water onsite in terms of saving water at the power plant. Instead, we need to be looking at the bigger picture, with water use also evaluated based on regional supply and the risk of local scarcity.

Indeed, we are already noticing an increase in rack densities, the problem being, denser racks require increased airflow rates. Which, if we continue to use the same outdated cooling technologies, will turn out to be incredibly energy inefficient.

This need to adapt has catalyzed the development of liquid cooling solutions, whether that be direct-to-chip or immersive. These ever-advancing alternatives appear to be pointing the industry in the right direction, enabling operators to keep lowering PUE while eliminating the use of compressor cooling.

RED recently worked on a case study[1] [LB(S2] that identified a 50 percent reduction in the energy used by the HVAC systems. In doing so, not only did the data center in question drastically reduce its direct water consumption, but also its indirect consumption (due to power generation) by driving up efficiency.

Rainwater harvest and bleed recovery

If a facility must use water-based cooling processes, another way to reduce water consumption is to enable rainwater harvesting, to reduce the use of the main water supply and therefore, the waste of resources.

Rainwater harvesting consists of the collection and storage of rainwater, usually from roofs, and also involves filtering processes to remove solids, organic materials and sediments, this also includes water treatment to neutralize nutrients and bacteria for evaporative cooling and/or humidification use. The level of treatment required depends on the water collection area, the level of contaminants, the type of cooling used – single pass or recirculatory – and the storage period before use.

Bleed recovery can also be implemented. Water is blown down from evaporative cooling systems in cooling towers to reduce the concentration of salts in the cooling water, which, if allowed to escalate, will lead to excessive deposits of solids in pipework and equipment. This in turn leads to eventual flow blockage, high pressure drops and a reduction in heat transfer coefficients. Blow-down frequency is controlled either by volumetric flow of make-up water, measurement of total dissolved solids (TDS) or by using a timer.

Of course, the rejected water will likely contain a high concentration of various salts, therefore the Cycle of Concentration (CoC) factor is used to determine how long cooling water can remain in the system before being blown down – the higher the CoC, the longer the residence time of the cooling water. Excessive blow-down can be avoided by defining this limit based on the water quality and chemical treatment being used.

Using reverse osmosis units, the recovery of bleed water can be achieved, although this requires high levels of energy consumption, ultrafiltration techniques (which use less energy) and side-stream filters to improve recirculating water quality, which in turn improves reverse osmosis performance. As such, the design of the bleed water system will need to be a compromise of both energy and water consumption; up to 75 percent recovery is available if water availability is scarce.

Where the location and local constraints of a project make sense, RED is now implementing the harvesting of rainwater and bleed recovery in an increasing number of its designs.

Trigeneration using absorption chillers

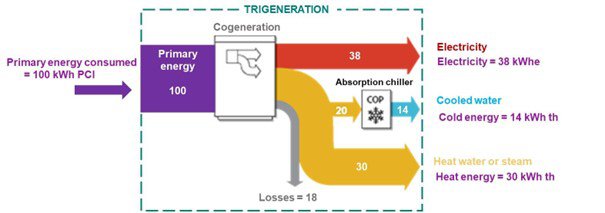

When it comes to lowering the environmental impact of a data center, overall energy and water efficiency are obviously key topics to address. On-site trigeneration actually tackles both of these challenges and turns out to be far more efficient than the design of traditional energy infrastructure.

Trigeneration systems have the ability to simultaneously generate electricity, heating and cooling from the combustion process. For data centers specifically, trigeneration is easily scalable and benefits from the ability to adapt with the ramp-up of the IT load.

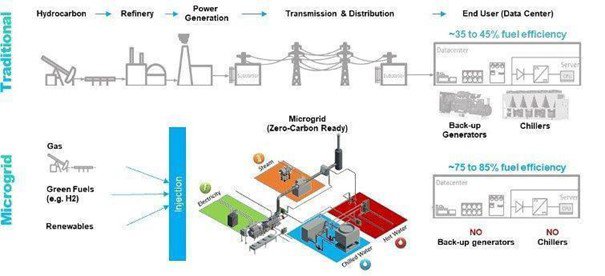

Engie and RED have developed a true expertise in the engineering, financing and operations of such energy systems across various industries. In terms of the primary energy delivered to a data center, this can be produced on-site, using gas turbines or gas engines capable of running on mixed fuels.

For now at least, natural gas remains the main fuel, but hydrogen and derivatives – as well as other green fuels such as biogas – already form a significant share of the fuel mix. In the future, gas engines and turbine generators will be able to accept an increasing blend of these green fuels, with the ultimate aim of running on 100 percent green fuels as supply chains develop.

These machines exhaust thermal energy through high-grade heat. The trigeneration approach then recovers this waste heat from the combustion process and transfers it to absorption chillers, enabling it to also serve the cooling needs of the data center.

This new approach to waste energy has turned out to be far more efficient than traditional designs (primary power from the electricity grid, with additional diesel generators on-site for back-up), drastically reducing the amount of net energy losses.

Recent studies led by Engie and RED have focused on a new data center project in the Middle East, where the energy assets’ design needed to overcome limitations posed by the national grid, in terms of its capacity and reliability, as well as having to contend with water scarcity. The aim? To deliver the greenest data center in the region.

Consisting of hydrogen-ready gas turbines and heat recovery steam generators to distribute the gas turbines’ waste heat to absorption chillers to locally produce cooling, the innovative energy design also boasts a solar farm that will, step-by-step, provide both electricity directly to the data center itself and to an electrolyzer, in order to produce green hydrogen that will increasingly be used as the main fuel for the turbines.

In doing so, the combined solution of turbines and absorption chillers allows a data center to achieve a better PUE and a WUE close to zero – even within the harsh conditions of the local environment – while energy and cooling productions remain secure, conforming to Tier III Uptime requirements.

Conclusion

Taking into consideration the local challenges data center owners and operators face today, RED and Engie can design, implement and operate innovative solutions, enabling drastic reductions – or even the complete elimination – of a data center’s water consumption.

More from Engie & RED Engineering

-

Sponsored Hydrogen-powered data centers: Utopian dream or next big thing?

How hydrogen and derivatives form a key strategic element of the carbon-neutrality solution

-

DCD>Talks the APAC Market with Wandrille Doucerain, Engie and Phil Reid, Red Engineering

In this DCD>Talk we discuss the future of the data center market in the Asia Pacific region with Red Engineering and Engie

-

Sponsored How do data centers provide low-cost, zero-carbon energy to local communities?

An introduction to waste heat export in supporting local communities