It isn’t, as you might expect, the rise of working from home and the Zoom meeting that will stretch data center networks to breaking point in the very near future, suggests CommScope’s Alastair Waite, head of global data center market development.

Rather, it is the explosion in IoT applications, and the combination of high speed and low latency demands on hyperscale and Edge data centers they will make in multitudes of time-critical tasks, running across multiple different applications.

“The reality is that it’s machine-to-machine communications that are about to cause the ‘data explosion’. There are going to be billions of IoT-enabled devices, all generating data. But the next step will be what are you going to do with all this data? How will you ‘mine’ it? What kind of AI and machine learning applications will you use?” asks Waite.

Not so long ago, one of the hottest topics in enterprise computing was ‘data warehousing’ – capturing as much information as possible – and, consequently, ‘data mining’. But this was almost entirely passive: the data would be collected, and later analyzed to see what could be learnt from it and applied to the business. Often, organizations wouldn’t even know what to do with all the data they’d captured, let alone how to begin using it.

But now, data collection is all about analyzing and using it on-the-fly, as it comes in, and turning it around right away. Increasingly, that data collection, processing and communication will be assisting activities such as autonomous vehicles and life saving medical applications where fast processing and low latency communications will be critical.

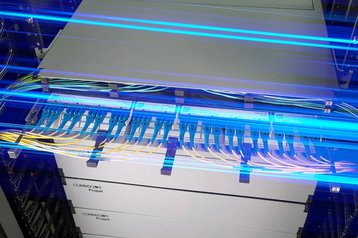

As a result, the biggest data center operators have already started a furious round of upgrades: higher density racks, better air conditioning systems to accommodate more powerful servers or even liquid cooling, GPUs to handle maths-intensive applications, and so on. And they all need to be supported by faster fiber platforms within the data center.

“A fiber platform is a channel comprised of patch cord, patch panel connectivity and backbone cabling that supports the organized presentation and routing of fiber in a data center or any network, in a logical and coherent manner,” explains Waite.

In other words, the fiber platform provides the physical infrastructure supporting multi-gigabit – and faster – network speeds within the data center, and does so in a way that reduces the mismanagement of cabling that can be typically associated with complex networks. It needs to be physically resilient and long-lasting to withstand rough handling, while providing ultra-low loss optical performance levels to ensure future-proofing to support successive generations of network upgrades.

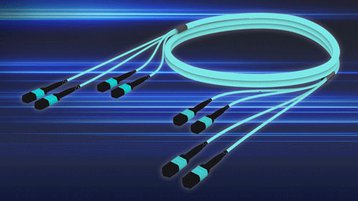

That, says Waite, is why CommScope developed and recently rolled out its latest Propel fiber platform, based around MPO8, MPO12, MPO16 and MPO24 connectivity making it capable of supporting data rates of 400G, 800G and even 1.6Tb.

The Propel platform provides MPO connectivity options to enable the migration of the underlying physical infrastructure to BASE-16, then to BASE-8 and back to BASE-16 again as the industry develops, all giving data center owners peace of mind that their production network can be future proofed, while enabling data center operators to roll-out upgrades with minimal disruption.

“What you get from Propel is a very high end, high-quality optical system, with ultra-low loss connectivity built in. This technology ensures the optical signal is as clear as it possibly can be, which will be critical as the data center moves to higher data rates,” he says.

Double whammy

This performance and reliability is the result of a number of innovations that CommScope has developed, in addition to the international standards that CommScope has contributed to.

Propel has been optimised to support PAM4 based transmission protocols – four-level pulse amplitude modulation – that has been adopted as standard for achieving Gigabit Ethernet speeds in excess of 200G. PAM4 is a modulation scheme that combines two bits into a single symbol with four amplitude levels. This doubles a network’s data rate, enabling 400G for short-haul transmission, according to technology specialist Precision Optical Transceivers. PAM4 will also be the modulation scheme for optical networking for years to come as the industry moves towards 800G, and then 1.6Tb.

PAM4 provides a doubling of capacity compared to previous approaches to modulation: non-return to zero (NRZ), which boosted bandwidth from 1G to 25G; and bandwidth from 40G to 100G was achieved using parallelisation of the 10G and 25G NRZ modulations. Both modulation technologies used host-side forward error correction (FEC) for longer distance transmission.

However, the massive increase in bandwidth enabled by PAM4 could come at a cost in terms of the signal-to-noise ratio (SNR). “With PAM4, instead of ‘one’ or ‘zero’, you’ve got four levels, which means you have less room for noise because now you're trying to squeeze four levels into an eye diagram, where you previously had two,” says Waite.

CommScope has tackled this potential challenge by introducing an APC (angle physical connector) polish to its multimode portfolio of MPO trunk cables.

Traditionally in single-mode networks where optical signals are transmitted across a long distance, the fiber had what’s called an APC finish that helped reduce noise. “With an APC polish, nearly all optical noise gets reflected up and out of the path of the signal and into the cladding of the glass,” says Waite. “Whenever you put two fibers together, you can get ‘backscatter’ or ‘reflection’ – a type of optical ‘noise’ that can go back into the transceiver and swamp the signal across those four levels.”

CommScope’s solution introduces this angled finish to the multimode MPO trunk cable connectivity (alongside the already existing single mode APC finish) provided by the Propel fiber platform, this approach greatly reduces the ‘noise’ that is often associated with lower quality connectivity that can sometimes be found in the market and, therefore, improves the clarity and reliability of the signal when used in higher speed networks, says Waite.

“What we're introducing for the first time, alongside the traditional rounded UPC (ultra physical connector) multimode connectivity, is APC MPO connectivity. This is in response to requests from the early adopters – the largest cloud and hyperscale providers – who are moving to 400G and even 800G, and are concerned that there will be too much system-based interference, so they’re starting to investigate that angled finish.

“Transceiver manufacturers have introduced that angled finish as well for 400G multimode, so where our multimode MPO patch cords connect directly to the optical equipment, they will also have that APC finish as well.

“Of course, we also offer systems with the traditional UPC finish, as well. However, moving forward, those data center operators with an eye on the future and 400/800G migration, should consider deploying a Propel platform with APC MPO backbone connectivity. And then, when they want to make the move to the higher data rates, we have the solutions in the Propel platform that will help them make that transition,” says Waite.

CommScope has its own manufacturing capabilities, and the optical performance data that CommScope is able to gather from its manufacturing processes makes it possible for the company to declare the transmission performance of a given a channel It also offers an extended application assurance backed by a 25-year system warranty. Moreover, much of the information that an installer or data center operator/owner might need about how a cable or panel was manufactured, can be acquired simply by scanning a QR-code attached to the panels, modules trunk cables and patch cords.

This kind of close relationship between design and manufacture is necessary to provide the assurances that data center users need that Propel will, indeed, work to the extremely tight tolerances that 400G and beyond demand.

“And because we have control over the manufacturing parameters that Propel is built on, we're able to offer tools like our Fiber Performance Calculator,” adds Waite.

This means that not only can prospective buyers check to ensure that the patch cords, panels and backbone cabling will all work to the highest standard in the environment they’re to be deployed in, but that CommScope can offer extended warranties based on the specific application. “We can also say to customers, ‘actually, you could stretch this channel a bit further,’ giving customers more flexibility to move their active equipment around their data center,” says Waite.

And that kind of flexibility is just what data center operators need in such a fast-moving industry.

To learn more about our new Propel™ modular fiber platform, which sets a new standard for flexibility in the data center while ramping up capacity to 1.6T and beyond, please visit the CommScope Propel™ resource page.

More...

-

Sponsored Hyperconnectivity hits the enterprise

The demands of hyperconnectivity - the need for ultra-responsive network connections - will place onerous new demands on enterprises and data center operators, warns CommScope's Jason Reasor

-

Structured cabling systems: the Fact File

A deep dive into everything you need to know about structured cabling systems

-

The hyperscale Edge: what it really looks like

And when will we really need it?