Toshiba’s latest generation of super heat recovery VRF air conditioners, the SHRM-i series, is the most efficient product on the market at part-load conditions.

The ground-breaking new range, available now, becomes the new industry benchmark in the competitive three-pipe VRF sector.

Toshiba believes performance ratings for systems at full capacity can be misleading. “In the UK, air conditioning only operates at maximum capacity for a small proportion of the time, “ says David Dunn, Toshiba’s commercial director. “For most of the time, systems operate at part-load – therefore it makes sense to focus on efficiency in this range.”

The new Toshiba system boasts a world-beating EER of 6.02 and COP of 5.63 at 50 per cent load (8hp unit). This translates into a Seasonal Energy Efficiency Rating (SEER) of 8, leaving rival systems behind.

A key to its exceptional performance is the use of up to three super efficient DC twin rotary compressors in each outdoor unit, with dedicated vector-controlled inverters. Unlike other makes, which share inverters between compressors, Toshiba uses a separate inverter for each compressor, giving ultra precise control of rotation speed in 0.1Hz increments, exactly matching output to load.

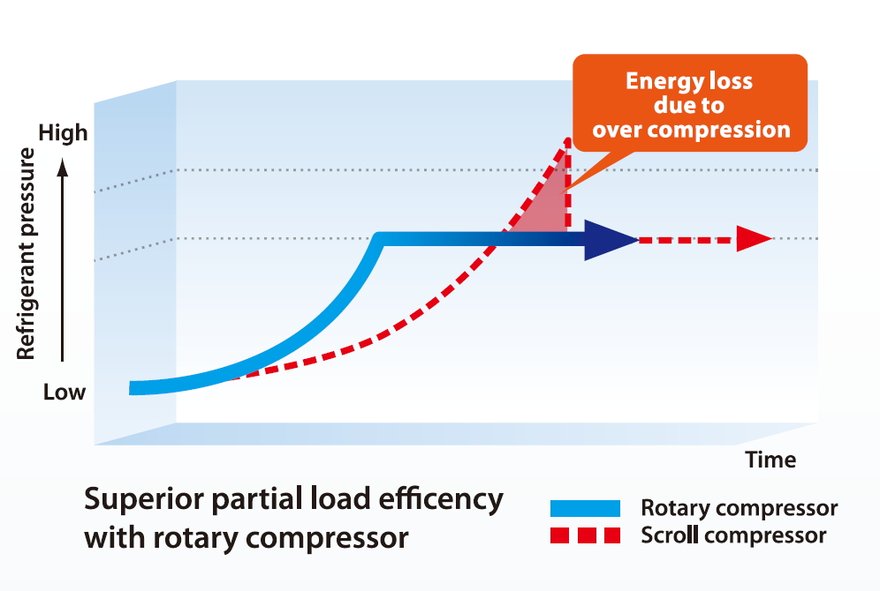

The latest Toshiba CD rotary compressors, operating on R410A, have a performance advantage over scroll compressors. To achieve a target load, scrolls have to initially exceed the required capacity; rotary compressors however can deliver the required output without any overshoot, avoiding energy losses.

The advanced technology results in a starting current of just 1Amp per system, a major advantage where the power supply is restricted.

The SHRM-i three-pipe system is designed to deliver simultaneous cooling and heating in large buildings such as offices, shops and hospitals, recovering energy from areas of excess heat and redistributing it to parts of the building requiring heating.

The system can also harness this energy using a unique VRF boiler accessory, to delivery low-cost domestic hot water for a building.

As a result, the requirement to eject waste heat to the atmosphere is significantly reduced, again boosting system efficiency.

Toshiba has focussed on developing longer pipe runs to give flexibility in installation. It has extended the maximum distance for indoor units to 190m, another world best-in-class. Total system piping length has been increased from 300m to 500m.

SHRM-i outdoor units are available in 8, 10, 12 and 14hp modules. Introduction of the larger chassis 14hp unit effectively extends Toshiba’s line-up from 11 to 18 models, adding six new mutiplex combinations between 32 and 42hp.

The company has given careful thought to the installation connectivity options with SHRM-i, to ensure flexibility of application. A full combination of header and Y-joint connections is available, enabling it to be installed virtually anywhere, subject to the improved maximum pipe lengths.

Outdoor units can be matched with a wide range of proven high efficiency, ultra-low noise Toshiba indoor units, including cassettes, concealed and slim duct units, high-wall and ceiling-mounted, floor-standing and console units.

The system can be connected to Toshiba’s new Smart control and monitoring BMS platform, giving full remote access and intelligent oversight of energy efficiency and performance.

David Dunn says: “End users are looking for reliable air conditioning that delivers guaranteed low running costs and a high quality working environment. We believe Toshiba’s new SHRM-i sets a new industry benchmark - for efficiency, flexibility and environmental protection - that will be hard to beat.”