With rapid advancements in AI technology and the availability of more powerful servers, the demand for data center infrastructure and more efficient cooling technologies only continues to rise.

According to the International Energy Agency, data centers consume about 200 terawatt-hours (TWh) of electricity—amounting to nearly two percent of global electricity demand. Based on that usage, data centers contribute 0.3 percent of all global CO2 emissions.

In data centers, racks of servers require the most amount of energy to operate, and server cooling equipment is close behind. Cooling solutions use motors to move air and fluid, so motor efficiency and lower power usage effectiveness (PUE) ratings are top of mind.

Today, data center designers are tasked with keeping power consumption, resource consumption and energy costs as low as possible while maintaining the right environment for reliable operations at scale. Data centers are also subject to a growing number of regulations that seek to minimize their infrastructure and, by extension, their impact on the planet.

Each of these challenges presents an opportunity to help data center designers get closer to achieving their sustainability and efficiency goals. Many of the companies developing the components that make up data center cooling systems are already working towards the same objectives.

Understanding how each component in your system supports facility wide design goals is one way to support progress in this industry. Here, we’ll review three motor considerations to maximize the sustainability of your data center cooling design.

Motor rightsizing

For fan systems and pump systems alike, finding a motor that has a high level of efficiency across a wide range of speeds and loads will have a significant impact on overall system efficiency.

In a data center, loads can vary widely depending on the time of day. Identifying a motor with a flat efficiency curve, regardless of load, optimizes the overall efficiency of the HVAC system. Infinitum motors run at variable speeds to save energy at off peak times, and efficiency is maintained with precise, demand-based controls.

Motor improvements can save upwards of 65 percent of energy depending on the application area. For example, variable frequency drives (VFDs) with silicon carbide MOSFETS can operate at higher switching frequencies and temperatures with fewer losses because their breakdown strength is ten times that of the standard components used in legacy VFDs.

This provides precise control over power, and by extension, energy savings for the motor system. A motor running at 80 percent of its rated speed uses 51 percent of the electricity of a motor running at 100 percent speed.

Even greater savings are realized at lower speeds; a motor plus VFD running at 50 percent of rated speed uses only 12.5 percent of the full-speed energy. With an efficient fan, the right motor can improve wire-to-air efficiency too.

Rightsizing for fans

Selecting a custom motor that delivers high levels of efficiency across a fan’s peak power and normal operating speeds can have a meaningful impact on the system’s overall performance. Infinitum’s advanced EC motors can be customized to meet horsepower, speed and torque requirements for high efficiency across a wide range of load conditions.

With a PCB stator design, Infinitum motors are innately more efficient because there are no core losses. Most traditional motors feature a heavy iron core with copper windings. This configuration causes eddy currents, and by extension, losses.

Infinitum makes it easy to rightsize motors on an application-by-application basis. The Aircore EC Motor Selection Tool helps fan OEMs select a properly optimized motor to fit the fan system.

Custom name plating allows designers to get close to the exact motor configuration needed, and it reduces input current requirements, which can add up to significant energy and electrical equipment savings for the whole system.

A saving of 5.6 amps for a motor that fits system requirements amounts to 22.4 amps for a single four-fan array module. For 100 fan arrays, that adds up to a saving of 2,2240 amps, which could reduce electrical infrastructure requirements.

For a detailed example of motor rightsizing, read ‘How to exceed customer expectations by rightsizing the motor for your fan system’ and explore different configurations with our motor selection tool. There, you’ll find information on torque, speed, input amperage, efficiency and size.

Rightsizing for pumps

Many of the benefits conveyed above apply to pumps too. With the United States Department of Energy (DOE) proposing new energy conservation standards for circulator pumps, there’s urgency to design for higher efficiency and better reliability.

Circulator pumps are usually overlooked for energy efficiency upgrades due to long, expensive design cycles, but new technologies are making these upgrades worthwhile. For more information on pump efficiency, read ‘Five ways to maximize energy conservation in circulator pumps with electronically commutated motors.’

Operating the motor

In the context of data center infrastructure, server cooling, and by extension, motor operation is one of the largest contributors to carbon emissions, so prioritizing a more efficient motor leads to significant savings over time.

For example, using the highest efficiency motors available (which corresponds to IE5 or NEMA Premium levels) could save 5,800 gigawatts of electricity – the equivalent of taking 16 million cars off the road. A motor that is more efficient, even by a few percentage points, makes a difference over a 20-year lifespan.

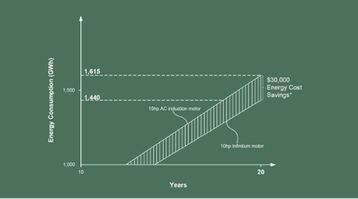

For Infinitum motors, energy consumption during operation is based on standard and published data on power, operating time and the efficiency of the motor plus VFD. Compared to a 10HP AC induction motor plus VFD with IE1 efficiency, the Infinitum motor system was found to produce 10 percent fewer CO2 emissions over a 20-year period of operation (Figure 1). That amounts to $30,000 in energy cost savings.

Running 1,000 Infinitum motors for one year alone reduces carbon emissions by 80,000 metric tons of CO2, which is equivalent to the electricity use of 15,000 homes over the course of a year. The compounding impacts of motor improvements underscore the importance of implementing even smaller changes as early as possible.

Sustainable design

Physical space is at a premium for data center designers, so equipment size and footprint are central considerations. With a more compact, axial-flux design and a thin PCB stator, motors can be up to 50 percent smaller and lighter.

Selecting this kind of design reduces the overall space required for air handling and other cooling infrastructure. When cooling systems are closer to the computing equipment that creates heat, they’re more effective at removing it. Smaller, lighter motors also make for easy installation and maintenance.

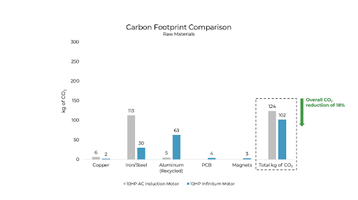

These designs also reduce the use of raw materials and incorporate end of life (EOL) management to minimize waste. Infinitum uses information about the procurement and refinement of the materials used in our electric motors as a proxy for the carbon footprint that results from production.

The most common materials used in motor manufacturing are copper, iron/steel, aluminum and magnets. Unlike other motors, Infinitum also leverages printed circuit boards (PCBs). Each of these materials is assigned an emissions factor that indicates how much energy it takes to transform it from a raw material to a fabrication-ready state.

Our current impact reporting methodology shows an overall CO2 reduction of 18 percent for a 10HP [AL1] Infinitum motor compared to a traditional 10HP AC induction motor (Figure 2).

Considering the end of life for equipment is also a key aspect of a sustainable data center. Operators are tasked with managing refrigerants and gases along with valuable materials like aluminum, steel and magnets that shouldn’t end up in a landfill.

At the end of a motor’s operational life, there are three main options: landfill, recycling of materials or remanufacturing (i.e., reuse of components). Infinitum motor components can be reused, compounding the reduction in CO2 over each generation.

At the end of the day, the right motor can help bolster your sustainability claims, improve efficiency and minimize energy costs for data centers. For an overview of mounting schemes for Infinitum motors in fan arrays, read ‘Fan cube & fan array design asset’.