The safety challenges and considerations of integrating immersion cooling into your data center design, construction, and/or operation require special attention.

This is especially important as it relates to the cooling fluids used and the hazards associated with deploying this new technology.

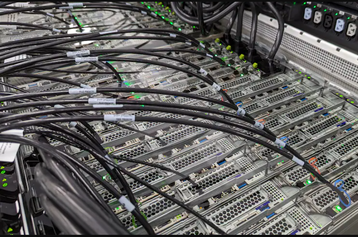

Immersion cooling, also known as “direct liquid cooling,” is a technique used for computer, battery, and motor cooling when electrical and electronic components, including servers and storage devices, are mostly or fully submerged in a thermally conductive, but electrically insulating liquid coolant.

However, despite the benefits, there are concerning safety challenges and considerations that must be addressed. Since ordinary water is conductive electrically and can harm electronic equipment, dielectric liquids are needed to prevent electric shock or equipment damage.

Further, because of the amount of heat generated in high density and AI computing, the dielectric liquid used needs to have a high specific heat capacity, thermal conductivity, and must be non-flammable or have a sufficiently high flash point to reduce fire risk.

Another consideration is the availability of the dielectric liquid in the commercial marketplace as there must be a sufficient supply of the dielectric liquid to support a large data center operation and ensure uninterrupted operations.

Finally, in selecting a cooling fluid, longevity, compatibility, low weight, temperature range, cost, viscosity, sustainability, and legal trends/risks are considerations that must also be addressed.

Hydrocarbons vs. fluorocarbons

In general, the dielectric liquids used in immersion cooling processes within a data center fall into two categories: hydrocarbons and fluorocarbons.

Hydrocarbons are organic compounds containing carbon and hydrogen (C-H bonds), while fluorocarbons, like perfluoroalkyl substances (PFAS) or “forever chemicals,” are highly stable compounds with carbon and fluorine (C-F bonds).

These dielectric liquids are typically used in single and two-phase applications, which are simply differentiated by whether or not the cooling liquid turns into a gas during the cooling cycle.

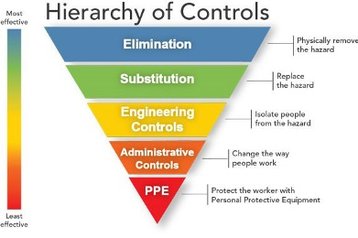

Proactive and robust hazard recognition, evaluation, and controls are imperative when deploying immersion cooling systems in a data center.

Beyond the traditional hazards, for example, pinch points, working at height, hot surfaces, and splash, immersion cooling introduces several additional and unique safety considerations.

One primary hazard is the potential for electrical accidents and exposures due to the electrical equipment as well as the close proximity of cooling fluids to live components, especially the submerged servers which can potentially generate hydrogen fluoride (HF), a toxic gas, if an arc flash should occur.

As such, it is essential to recognize and address these risks through comprehensive electrical safety studies and measures, including insulation and isolation techniques.

Another primary hazard relates to the choice of the cooling fluid itself, which requires careful consideration, as some dielectric fluids may pose health and environmental hazards. The long-term effects of using “forever chemicals” on the environment, animals, and human health are still relatively unknown.

The NIOSH Hierarchy of Control Methodology

Once hazards have been identified and prioritized, the use of the NIOSH Hierarchy of Control Methodology is an effective method to reduce the risks associated with immersion cooling.

For example, risks from cooling fluid-related hazards can be mitigated through the implementation of modified/custom ventilation systems, environmental controls, and strict handling procedures to sufficiently control the working environment.

Comprehensive training for personnel handling the cooling fluids is also needed, emphasizing safe operating procedures and emergency response protocols to ensure a secure working environment. By conducting comprehensive hazard assessments and evaluations coupled with adopting robust hazard control measures, your data center can harness the benefits of immersion cooling while prioritizing the safety of both the equipment and personnel.

Despite these hazards, immersion cooling is proving to be an effective method to remove heat in data center environments and has some safety advantages, which makes it an appealing choice in certain circumstances as follows:

- Hardware: The method of submerging hardware components in a dielectric liquid minimizes the risk of overheating, providing enhanced thermal management. This can lead to increased overall system reliability and a reduced likelihood of hardware failures due to heat-related issues as well as reduced overall maintenance cycles for personnel.

- Energy Efficiency/Water Conservation: Improved energy efficiency and reduced water usage are notable positives as they can support company sustainability initiatives and commitments. Relatedly, immersion cooling systems, operating at lower temperatures than their traditional air-cooled counterparts, also foster a safer work environment.

- Fire Prevention: The closed and sealed nature of immersion cooling system setups mitigates the risk of dust accumulation and potential for electrical fires, enhancing the overall safety profile while the dielectric liquid used in immersion cooling systems can function as a natural fire suppressant, providing an additional layer of protection.

The safety benefits of immersion cooling, including improved thermal regulation, reduced risk of hardware failures, energy efficiency improvements and total water savings, and enhanced fire safety, make it a compelling choice in scenarios where these considerations are paramount.

Further considerations

While immersion cooling appears to be highly efficient and delivers notable benefits, several safety challenges and concerns still warrant careful consideration as follows:

- Energy Usage: Even with the rack density advantages of these huge gigawatt data centers and the potential for ultra-low PUEs, immersion cooling consumes a tremendous amount of energy, which does not align with company sustainability initiatives and commitments.

- Weight/Mass: Increased weight associated with immersion cooling system setups is significant as the dielectric liquid adds substantial mass to the system. This additional weight can pose challenges regarding structural integrity and safe transportability. Any immersion cooling system build or retrofit must include a structural analysis to ensure that the data center floor can handle the weight of the equipment, tanks, and cooling fluid as well as a safe transportability plan. Further, any thoughts of elevating immersion cooling systems to a second or higher floor of a data center require special consideration and attention from a safety perspective.

- Hardware/Environmental Monitoring: The need for specialized hardware and environmental monitoring to ensure personnel safety as well as the compatibility of the immersion cooling systems can drive up costs significantly, making it a less economically viable option for some applications.

- Procurement: Vendor agreements may need modification and/or warranties may be nullified/compromised as the equipment may not have been designed or tested for immersion cooling while readymade equipment is expensive to meet safety and operational specifications.

- Space: The space requirements for immersion cooling system setups are also considerable, demanding dedicated areas with appropriate infrastructure. Safe transportability measures and lifting devices are also needed because the racks typically lie horizontally inside tanks rather than vertically, and the servers need to be lifted in/out of the tanks for installation, replacement, maintenance, and/or servicing.

- Leaks/Spills: The risk of leaks or spills from the cooling fluid introduces additional concerns, not only for the hardware itself but also for personnel and the surrounding equipment. As such, maintenance and housekeeping become a critical aspect, requiring meticulous attention to prevent and address leaks promptly, adding to the overall operational complexity and potential safety concerns.

- No Approved Testing Method and Procedures: The safety challenges are further complicated by the fact that there are no government-approved testing methods and procedures for most of the dielectric liquids; other chemicals have to serve as surrogates to monitor exposure limits, which creates uncertainty with occupational exposure levels (OELs).

- No Threshold Limit Value – Short-Term Exposure Limit (TLV-STEL): Most dielectric liquids have no TLV-STEL. Accordingly, the American Conference of Governmental Industrial Hygienists (ACGIH) TLV Committee advises controlling short-term peak exposures above the TLV-Time Weighted Average (TLV-TWA) for substances with no TLV-STEL, even if the eight-hour TLV-TWA is within recommended limits. Limiting the short-term high exposure is intended to prevent rapidly occurring acute adverse health effects resulting from transient peak exposures during a work shift.

- Industrial Hygiene Modeling and Monitoring/Computational Fluid Dynamics: Since dielectric liquids turn to gas in two-phase immersion cooling and can be released into the data center hall via venting, open lid covers, etc., it is important to formalize and document worker OELs as well as the vapor patterns of the gas to ensure the safety of personnel.

- Forever Chemicals: As noted above, the use of “forever chemicals” in immersion cooling applications introduces potential environmental and health concerns because the long-term effects on the environment, animals, and human health are still relatively unknown, and some of these compounds are persistent over time and resistant to degradation, raising potential toxicity concerns. Importantly, however, much is still unknown about these chemicals.

- Emerging Legislation/Legal Trends: On a global scale, emerging legislation and legal trends are not looking positive for “forever chemicals.” In fact, several large companies have stopped immersion cooling research and/or production of “forever chemicals” because of the potentially toxic side effects, potential for widespread environmental contamination, and the associated multi-billion-dollar lawsuits that come with producing and/or using these products.

Simply put, immersion cooling appears to be highly effective and, on the surface, is relatively safe. However, there are limitations to its applicability. Immersion cooling still has many safety unknowns and risks, which may eventually affect its practicality and usefulness. As such, from a safety perspective, the jury is still out regarding immersion cooling.