Everyone in the energy game knows the big trends in power are sustainability and localization. That is sustainability through Renewable Energy Resources (RERs) and localization through microgrids, on-site generation, and local storage.

In this context, the question is: "Does sustainability of the behind-the-meter power chain require new thinking?" At first glance, the answer to this is a no-brainer.

This in turn causes professionals across different industries to begin debating which battery they should choose for that particular local energy storage solution.

But instead of starting with which battery, we should instead begin with evaluating our needs - from the level of protection required, the budget, and how sustainable the solution is.

Local and global

A product of both the localization and global sustainability trends will be more local power storage.

Change is also coming to behind-the-meter on-site power chains. It is clear that whether in hospitals, factories, or data centers, wherever power storage needs to be in close proximity to the load, all building operators are looking differently at how to secure power and keep the lights on.

Here the storage options extend beyond chemical batteries to various mechanical storage technologies (but in truth, the only currently viable mechanical option for local power is kinetic flywheels).

In such environments, even a high-level examination of battery technologies should give cause for concern, and pause for thought.

Every solution can be judged through similar sustainability factors. Especially important are factors such as specific raw materials, manufacturing processes, recycling, supporting infrastructure needed, and regional regulations.

This is necessary when it comes to squaring the sustainability circle while providing the necessary backup.

Sustainable energy storage – what gives with batteries?

A quick look at existing and new battery types being developed reveals a lot.

For industrial applications that require energy storage close to the load, the familiar battery storage options are rechargeable lead-acid batteries that use lead dioxide as the positive electrode; metallic lead as the negative electrode; and sulfuric acid as the electrolyte.

From a sustainability perspective, the production and recycling processes of such batteries can lead to lead pollution and environmental damage. Lead is a toxic heavy metal that can harm ecosystems and human health. In many places lead acid is being phased out and replaced with newer technologies.

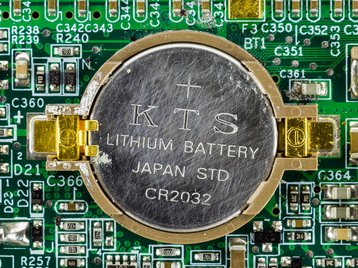

Everyone is familiar with Lithium-ion (Li-ion) batteries. Lithium is the active material for both the positive and negative electrodes. They are known for high energy density and long cycle life. However, their life impact and environmental costs are difficult to calculate, and it is hard to establish consistent sustainability. There remain few recycling options for large-scale lithium-ion batteries. There are also the environmental management challenges and costs associated with large Lithium-ion deployments to consider.

Nickel-zinc (Ni-Zn) batteries are rechargeable and use nickel oxide hydroxide as the positive electrode (cathode), zinc as the negative electrode (anode), and an alkaline electrolyte often used in various applications, including consumer electronics and hybrid electric vehicles. As with lithium the extraction of nickel and zinc can have environmental impacts, and the recycling of these materials may not be as widespread as with other battery types.

Batteries are not the only game in town

Flywheel energy storage-backed UPSs provide an integrated solution where the frequency and voltage management are aligned with workload requirements.

Kinetic flywheel energy storage is reliable, efficient, low maintenance, low footprint, and sustainable from cradle to grave. In data center and industrial applications, kinetic energy storage can provide several minutes of emergency response power at MW-plus capacity.

Kinetic flywheels are modular and relatively small. Unlike battery systems they don’t degrade with every use, nor do they require additional HVAC infrastructure for efficient operation and to remain stable and reduce fire risk.

All infrastructure is being measured for sustainability. The world is moving to a time of more environmental impact and sustainability reporting. It will be interesting to see what Scope 1, 2, and especially 3 emissions data is reported for large-scale battery deployments in the coming years.