In the last issue of the magazine (#50), we explored how data centers use uninterruptible power supplies (UPSs) to power through grid outages.

In this feature, we will explore the two main types of uninterruptible power supply (static and rotary UPS systems), when each type is best deployed, and the conditions these systems work best in.

The design of a power system inside a data center is entirely dependent on the continuity requirements of the IT load. If the customer can live with shutting down all ICT services for either maintenance or failure, then the overall system design can be quite simplistic and low-cost.

However, for the majority of data centers, a shutdown of ICT services is essentially not an option. In such cases the power must have two different power paths to each server - this is known as concurrent maintainability. The stronger the continuity requirement for the IT load, the more complex and costly the power system design will be. For the IT load to survive a worst-case scenario, another level of resilience is needed - otherwise known as fault tolerance.

As we have seen in the previous feature, the IEC Standard classifies UPS systems through three metrics - Input dependency, Output Voltage Waveform, and Dynamic output performance ensuring common naming conventions between manufacturers.

When looking at these systems through a data center lens, things tend to become simpler - static UPS and rotary UPS.

The static UPS

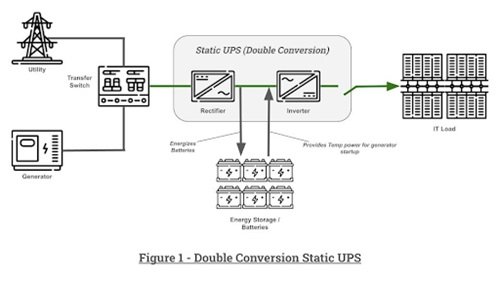

The static UPS is called “static” because, along its power path, there are no primary moving parts. A typical static UPS used in the data center space usually consists of a Rectifier, an Inverter, and a set of batteries. A typical representation of a static UPS can be seen in figure 1.

Within a data center, the most prevalent type of static UPS is a double conversion topology, in which the incoming utility electrical current is converted from AC to DC by the rectifier.

This keeps the batteries charged, and is then converted back into a clean AC sine wave. This sine wave is clean due to the constant and continuous electrical current output from the set of batteries.

Regardless of how the internal topology is set up, there will be a point where the DC current interfaces with the batteries - i.e., it keeps the batteries charged. When the input power cuts off (utility failure), the IT load runs off the set of charged batteries - giving enough time for the on-site generator to start and warm up.

A three-phase static UPS usually has a runtime of anywhere between five to 30 minutes. This runtime is calculated based on the size and the criticality requirement of the load and the capacity of the batteries. The capacity of the energy storage system is generally calculated to allow for enough time for the generator to start while still maintaining the availability of the IT load.

Should the generator fail to come online, the UPS will be configured to properly shut down the load instead of just cutting power to it.

Static UPS systems are characterized by their scalability and reliability. With fewer moving parts by design, the mean time before failure for each component is higher than with rotary systems. Further, the static UPS system is scalable with modules added or removed to account for changes in load.

That is not to say that they are without disadvantages, mostly arising from the energy storage system’s reliance on batteries. Because the whole IT load is kept alive by the batteries, the overall system footprint is relatively large. Maintenance and replacement is an ongoing task with multiple sets of batteries. The system can also be quite heavy, posing more installation and servicing challenges.

The rotary UPS

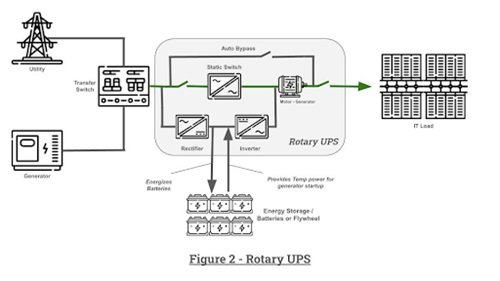

In a rotary UPS, the output sine wave is the result of rotating generation - like a dynamo or a flywheel, as opposed to the static UPS where the output sine wave is generated directly from the energy storage system.

In the rotary UPS represented in figure 2, a motor is fed directly from the utility, which in turn provides mechanical power to the generator component to effectively generate a clean AC sine wave that is fed directly to the IT load.

When the UPS detects that utility voltage and frequency parameters are out of the required limits, the rectifier and the inverter provide controlled power to the motor, which is coupled to the generator fueling the IT load.

In case of a full blackout, a set of batteries provide power to the motor which will provide sufficient runtime for the standby generator (outside of the UPS) to ramp up to full speed and provide power to the facility.

Unlike static UPSs, rotary UPS systems are not modular and therefore need to be oversized to accommodate any future increases in the load. They also require additional ventilation as motor-generators will fill work areas with fumes during runtime. In the majority of cases, they are placed in a special outbuilding or in a custom-built room.

Both static and rotary UPS systems are considered highly reliable. Because they don’t rely on large battery capacities to power the whole IT load and instead have a motor, rotary UPSs can have a longer lifespan if properly and frequently maintained.

Due to their nature, rotary UPS systems are better suited for a centralized power architecture approach to the data center, whereas static UPS systems can lend themselves to a more distributed solution. Rotary UPS systems are also ideal for environments where multiple short inrush currents of power are expected, such as satellite stations or broadcast stations where power-hungry amplifiers turn on or off randomly.

Within the data center space, rotary UPS systems represent a niche in the market and are mostly found within Europe. Static UPS systems dominate the data center space, but as load availability requirements climb a mixture of UPS types can be found in data centers with loads in the megawatts.

As with everything within the data center space, there is no one-size-fits-all approach and this is especially true when designing its power train. Each type of system comes with its own advantages and disadvantages, and careful consideration must be given to selecting one.

In the next part of this series, we will be digging deeper into the most common types of actual UPS systems currently deployed in data centers.