The Department of Energy and Climate Change (DECC) is turning its interest in carbon reduction into funding for a UK startup to help it place its monitoring tool for data center energy efficiency into two large-scale data centers for testing.

Back in 2010, Cambridge UK-based Alquist won the DatacenterDynamics Leaders Award for Future Thinking and Design Concepts for its Celsius tool, which uses laser technology designed originally for the oil and gas industry to measure temperature variants at a granular level throughout the data center.

Since then it has carried out smaller tests of the technology but now DECC has provided Alquist with £1m in funding that will see the solution rolled out in a large Verizon data center and by Schneider Electric, which will use it as an add on for its StruxureWare data center infrastructure management (DCIM) solution for a large customer.

Alquist chairman and founder Toby Burton said the UK Government, after focussing heavily on business and other industries, is now looking for ways to promote carbon reduction in data centers.

He said while it will not promote an end product the Government is happy to support trials for technology that can help bring carbon savings to the energy-intensive industry.

“They have seen what the potential savings can be through energy efficiency efforts in the data center space in the UK and view this (potential data center energy savings) as pretty striking,” Burton said.

“They can also see the potential for the UK to become a global leader in green data centers, with knowledge we can take to the US and Europe but you need to have data on those energy savings first.”

Burton said with both projects the first goal is to take measurements of temperature throughout the data center then to identify areas where energy savings can be made.

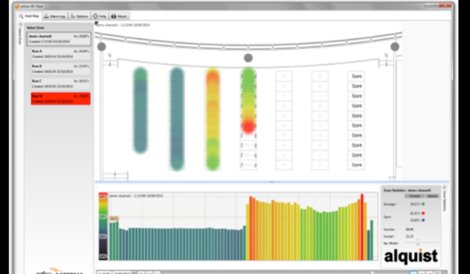

Celsius uses software linked up to fiber-optic cable that can be placed throughout the data center environment over racks, busbars, batteries and near air conditioning units to take readings for every one or two meters of fiber of the heat in the surrounding environment using a laser beam shot through the cable.

“It is quite complicated physics,” Burton said.

“The laser is the expensive bit but once you have it, you have it. When you send a signal down fiber optic cables there is a noise that comes back called interference. As the cable gets hotter it absorbs some of this energy (light), giving a terribly precise measurement of what is refracting back in noise,” Burton said.

“You can lay the cable all around the room and have photons bouncing back from five meters to measure the amount of energy there.”

The technology has been used in the past to measure the flow of oil through 60km to 100km pipe lines. It measures temperature at the top and bottom of the pipe and if there is a difference in the temperature the oil and gas company knows there is a gap in the pipe, signalling an uneven flow.

The Verizon and Schneider Electric deployments will start by measuring chiller load and will then go on to provide more details.

Verizon technical facilities lead for Europe Natalie Hooper said it will be a cost-efficient way of gathering necessary temperature information to proactively manage equipment more effectively.

“Operating cooling systems efficiently whilst avoiding hotspots is one of the key challenges faced by data center operators,” Hooper said.

In the Schneider case, Celsius will send information back into StruxureWare which can then allow for the automatic provisioning of services inside the data center.

“The data can automatically trigger alerts and gives a floor plan into the system so operators can see what is happening at 15-second intervals,” Burton said.

The system is not only used for carbon reporting, with thousands of real-time sensors used in both projects, it will also help the operators reduce risk, according to Burton.

“There are occassions, they are very rare, when a busbar explodes because it gets too hot. At the moment there is very little you can do to monitor how the busbars are performing.

Thermal imaging for this can be quite expensive. But with Celsius, because you have already paid for the laser, you can do this as well to get a precise temperature map for the busbar,” Burton said.

The DECC funding is paying for these two deployments but Burton said he hopes the outcome will be a solution tested with success in two large-scale developments, a result which comes with the possibility of commercial Verizon rollouts and a Schneider Electric DCIM partnership.