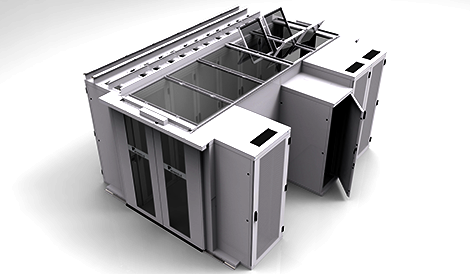

Minkels announced its Next Generation Cold Corridor modular aisle containment solution that separates hot and cold airflows in an energy-efficient manner.

The company launched the first version of the Cold Corridor system in 2006 and the latest design, known as the Next Generation Cold Corridor, Minkels’ R&D department caters to 'increasingly dynamic user requirements.'

“Virtualisation and cloud computing have given data center dynamics a considerable boost,” says Jeroen Hol, CEO at Minkels. “As an extension of this development, users are expressing a growing need for scalable and flexible data center solutions. They want to be able to conveniently upscale or downscale a data center whenever necessary. Cost considerations also play a role in this call for flexibility.”

Minkels’ R&D has improved airflow management over the previous version and new roof panels were designed for a high level of light transmission. The new design enables the plug & play installation of monitoring sensors.

One available module means the compatibility of the Cold Corridor with water mist fire suppression. This module contains a so called ‘pivot roof’ system, which connects the roof panels to the water mist fire suppression. Once a certain temperature is reached the roof panels will collapse to let the water mist inside.

In the field of access & access control there is a module available with automatic sliding doors, and a mechanical self-closing module, as well as a manual option – either synchronised or not.