For UPS systems, various backup systems are available: Conventional VRLA (lead acid) batteries as well as super capacitors and flywheels. Now, lithium-ion batteries can be assembled in modules which compete with the leading technologies that provide very high discharge currents at very short autonomies.

Batteries versus flywheels

UPS systems have to provide high discharge currents to keep data centers running, but only have to power them autonomously for a limited period - a short autonomy time.

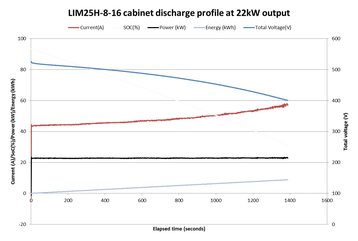

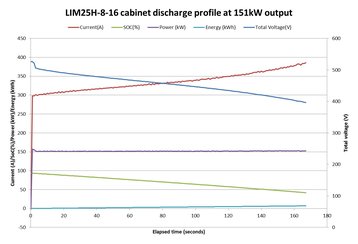

The optimum autonomy range of an electrical energy storage system is defined by parameters such as price, weight, dimensions, performance and efficiency. The autonomy range of a flywheel system is very small – only 10 to 60 seconds. Li-ion batteries cover this scope, but also provide a technical and economical alternative with autonomies extending up to five minutes, or even more.

In most cases, traditional valve-regulated lead-acid (VRLA) batteries are still the more cost-effective solution.

Considering space requirements, Li-ion batteries can have a much higher energy density than a flywheel. A flywheel UPS delivering 100kW requires a space of 0.6 sq m, while a UPS system built with Li-ion batteries at 300kW requires only 0.5 sq m.

The solution with lithium-ion batteries outperforms the flywheel technology in further aspects. It is more energy efficient: in standby mode, LI-ion batteries have almost no losses, while a flywheel system needs a constant energy supply to maintain the vacuum system and support the magnetic mounting.

Flywheel systems do have a clear advantage in their operational temperature range: they work in a wide temperature range, whiyle Li-ion batteries require a temperature between -20°C and +45°C. However, this range is sufficient for most applications.

Both technologies are well equipped for operational safety, with systems that monitor the operational conditions at any time. For example, Yuasa’s LIM25H modules have an integrated battery management system with sensors and control units that manage the charging state of each cell as well as of the complete module. A master battery management system monitors the operation and controls the MCCB (Moulded Case Circuit Breaker) which can disconnect the electric circuit if necessary.

Maintenance and charging

Li-ion batteries are maintaned with a battery management system (BMS), which can be operated remotely. Flywheels have mobile parts which have to be maintained and replaced regularly by qualified personnel.

Recharge time is also important in a backup system. Flywheel systems always regain full capacity after a few minutes, while Li-ion batteries will have a recharge time that can vary from a few minutes to several hours to restore 100 percent capacity, depending on the depth of discharge.

In principle, the number of charge/discharge cycles provided by a battery backup system depends on the depth of discharge. The more capacity is discharged during one cycle, the fewer cycles will be available over the total battery service life, and vice versa. This is due to the electrochemical process in a conventional battery.

Inside the flywheel, there are no electrochemical processes or any electrochemical corrosion - so the flywheel is the champion regarding the number of cycles.

However, cycles are not relevant in UPS applications: In standard UPS operation, batteries are not permanently discharged and charged, except in the case of failure of the main energy supply.

Design of a Lithium-ion module

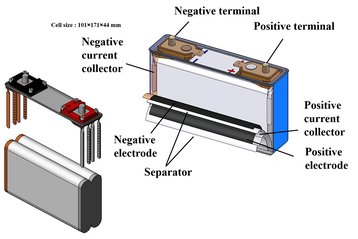

A high performance lithium-ion cell such as the LIM25H has a prismatic structure and is built in an aluminium case, which allows for easy and cost-effective assembly of the modules, while using the space inside the module efficiently. This leads to a higher module energy density than with cylindrical cells.

Positioning terminals a opposite ends minimizes the risk of short circuit and facilitates the inter cell connection inside the module. Cylindrical cells have a high risk of short circuit with the terminals at one side, and the assembly of cylindrical cells with the terminals on opposite sides is much more elaborate. Compared with the design of a pouch cell, the prismatic construction does not require an additional installation frame and requires fewer welded connections. Also, the assembly of the inter cell connections is much easier. Each cell has an integrated BMS connection, and the aluminum case supports heat dissipation.

Eight LIM25H cells are connected in a LIM25H-8 battery module, with a nominal capacity of 25Ah and a nominal voltage of 28.8V.

Batteries win?

Advantages of LIM25H systems compared to the flywheel technology:

- Low energy demand: Li-ion cells do not require supply for continuous charging, wherever flywheels require a continuous energy supply.

- Lower maintenance costs: Li-ion modules have an integrated battery management system which allows for remote battery monitoring. Flywheels, however, have mobile parts which have to be maintained and replaced regularly by qualified personnel.

- Wide autonomy range: Li-ion batteries provide autonomies up to several hours whereas flywheels support autonomies up to 30 seconds or just above.

Raphael Eckert is group sales manager at Yuasa Battery (Europe) GmbH