Imagine waking up at 04:00 to an escalated BMS alert that your Dubai data hub has overheated. Over the course of a frantic morning, you learn that a cooling unit developed a fault and shut down, causing a thermal runaway event. You discover that the data center cooling was under provisioned and IT deployment was over the available cooling capacity, which crippled the N+1 resiliency.

The result? Total loss of service, contract defaults, fines and the loss of trust from a blue-chip client.

This scenario is dreaded by data center operators. To prevent it, IT systems and alterations data center infrastructure should be expanded in a manner that identifies, characterises, minimises or prevents risk.

This risk is often managed upfront, in the design phase of a new data center. Cooling systems may be designed with resilience in-mind and capacity carefully managed through DCIM and BMS systems. But as the data center IT deployment evolves, do you truly know the ability of your cooling system to adequately cool your new blade deployment without impact to resiliency? What will the impact of a cooling unit failure be? Can you afford to take the risk?

CFD modelling

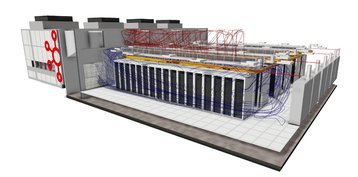

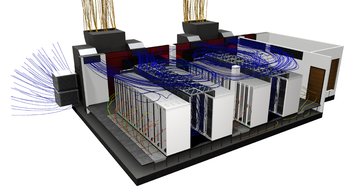

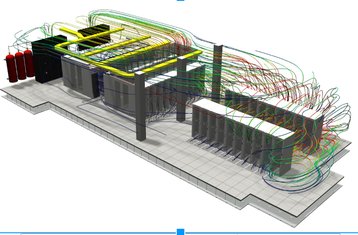

Computational fluid dynamics (CFD) can put cooling systems through their paces without risk to mission critical infrastructure. It uses simulations to verify cooling effectiveness, resiliency and availability during the audit, design, build and maintenance of critical facilities.

When CFD modelling is incorporated into the design process there are greater possibilities available to designers. For example, using CFD in the design process, Sudlows has found that conventional cooling systems can be safely used for higher rack power densities than previously thought best practice, giving greater flexibility to the end user.

It is not just data center designers that need a way to predict cooling availability to the white space: the same is true for data center operators – and many today are realising that CFD is a valuable tool to guide improvements. With CFD audits and CFD guided decision making, CFD data can hslp an operator to find additional IT capacity within a live data center which is reaching full capacity, without putting mission critical operations at risk.

Why validation matters

Through a thorough non-invasive audit, data center engineers use CFD to develop a computer model of the facility cooling system, capable of resolving the chaotic cooling airflows commonly found in all air-cooled data center configurations.

For best practice, engineering quantities such as momentum, pressure and heat transfer are translated into easily verifiable quantities including rack inlet temperatures, supply air grille flow rates and BMS sensor readings. The values from the model are validated against the audit data, and the CFD model is shown to be an accurate representation of the data center.

This verification step is crucial. Decisions made taking into account evidence from a non-validated CFD model simply adds further risk to the chain. There are a myriad of methods of CFD analysis available to the engineer, software designer or end user and due to the non-linear nature of the coupled partial differential equations running at the heart of CFD, even slight differences in modelling approach have the potential to produce drastically different results.

Summary: model it right

To ensure you are not making ill informed decisions, it is important to consider the basis of any CFD simulation.

- Understand the scenarios that are being considered – are they relevant to day-to-day operations? Is the scenario presented truly a worst case?

- A data center cooling system is made up of multiple components, each containing multiple subcomponents. As such, it is crucial that each is treated in a rational way - be sure to consider how each element of the cooling system has been modelled.

- It is likely that some elements of the cooling system have not been incorporated into the CFD simulation, with assumptions made in place. Ensure that these assumptions are carefully considered.

Ideally these will all be considered on your behalf by the CFD engineer: be sure to ask for a copy of validation document which summarise them.

Once verified, the CFD model is fit for use and predictive analysis can take place. Any activity, infrastructure change or load scenario that affects the data center cooling system can be assessed in-line with the facility resiliency goals.

We have seen that CFD is a powerful tool with great benefits to data center designers and operators and many organisations have already benefitted from its use in capacity planning, resiliency gap analyses and audit. With this year gearing up to be the hottest year on record, confidence that your facility is cooled by a resilient data center cooling system is needed now more than ever.

Sam Wicks holds the 2015 Award for DatacenterDynamics Young Mission Critical Engineer of the Year